-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistics Tools

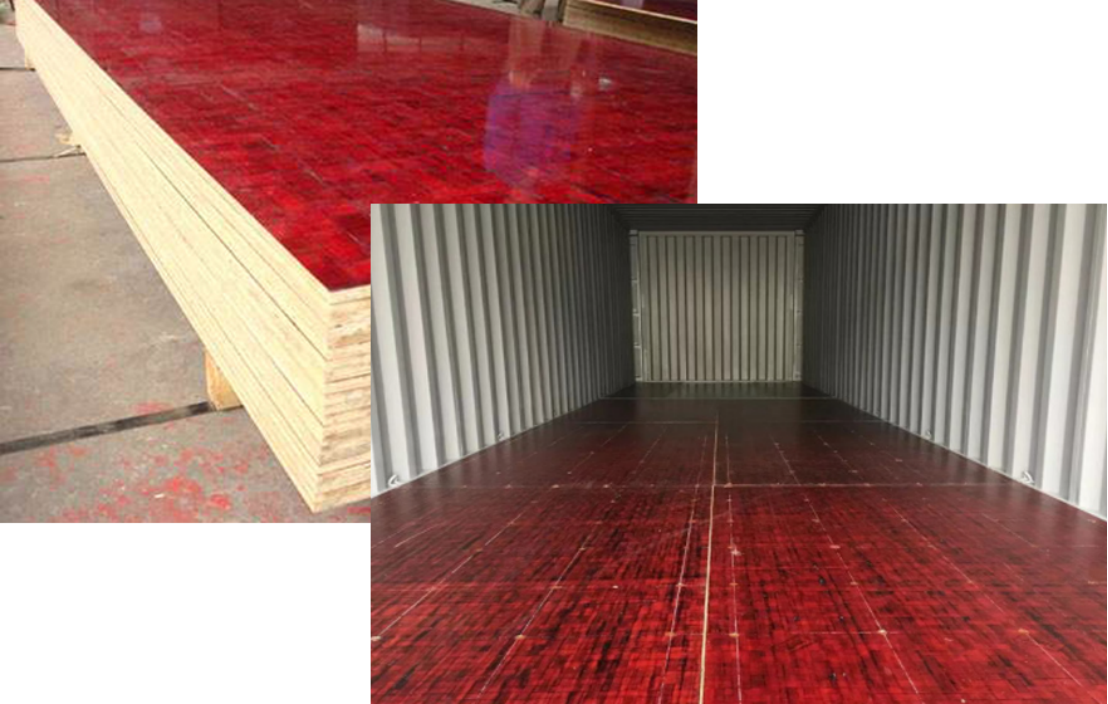

Container PartsCIMC Equilink | Container Bamboo FlooringOct 05,2022Container floor is an important part of container and the main load-bearing accessories. Because the floorboard will affect the safety and quality of cargo transportation, it is also one of the focuses. The traditional floorboard is mainly made of 19 layers of wood plywood with a thickness of 28mm made of tropical hardwood such as Apitong and Kerning from Indonesia and Malaysia. Due to the reduction of tropical hardwood resources in the world and the implementation of environmental protection measures, the raw materials used for container floorboard are limited. Therefore, it will be an inevitable trend for the development of container floorboard in the future to gradually adopt alternative materials and reduce the use of tropical hardwood.

Bamboo wood composite container floorboards refer to the plywood for container floor made of bamboo units such as bamboo curtains and bamboo mats as well as wood veneers, including plain bamboo wood composite plywood and covered bamboo wood composite plywood. Due to less and less hardwood resources available for traditional container floorboard preparation, container bamboo plywood is widely used because of its rich raw materials, excellent performance, low cost and easy automation production.

The bottom plate of container is the main load-bearing component, which requires high physical and mechanical properties. Therefore, it is particularly critical to form a complete container floorboard production system, including quality assurance system. The whole process of structural design, processing and performance testing must be considered. In the process of designing the container floor, the components of bamboo, the properties of wood and the surface materials are all important factors that must be considered. Among them, the position and direction, number of layers and proportion of bamboo have an important impact on the performance of the whole container floorboard, while the species, density, moisture content and thickness of wood will also affect the physical and mechanical properties of the floor to a certain extent. In addition, the amount of glue soaked in bamboo curtain, the use form of bamboo, the classification of bamboo and the thickness of bamboo curtain are the influencing factors of bamboo as the surface material. In the manufacturing process of the bottom plate, the production process, compression ratio and adhesive will not only affect the physical and mechanical properties of the bottom plate, but also affect the production time and production cost. As a structural material, the quality inspection and control of the container floorboard is a crucial link. The container floorboard must have good anti-seismic, impact resistance, aging resistance and other properties. Therefore, there are high requirements for the physical and mechanical strength of the container floorboard, including the bending strength, static bending strength, elastic modulus and other properties along and across the grain.

Maersk has carried out a 4-year global operation tracking assessment on containers equipped with bamboo wood composite container floorboard. And believes that the loading safety and service life of bamboo wood composite container floorboard can meet the target requirements, and it can completely replace the traditional tropical hardwood floorboard for container manufacturing.

In addition to shipping container floor, twist lock, container corner casting, Container Locking Device, Lashing equipment, Container Corner Post, container Cross Member, container Gasket etc. are all very good container parts sold by CIMC Equilink. Our customers will buy together with the above products.

If you are looking for container parts or shipping containers for sale, or you just have questions about container declaration and transportation , please visit us by email(info.equilink@cimc.com)or submit a quick quote.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文