-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistics Tools

ContainersGuidelines for Reefer Container TransportationSep 27,2023What are reefer containers?

Reefer containers are large temperature controlled containers used for transporting perishable goods, such as fresh fruits and vegetables, seafood, meat, dairy products, flowers, pharmaceuticals, film, and some refrigerated and frozen goods that may deteriorate if not maintained. Reefer containers are the only effective way to transport perishable items and other temperature sensitive goods over long distances in large quantities.

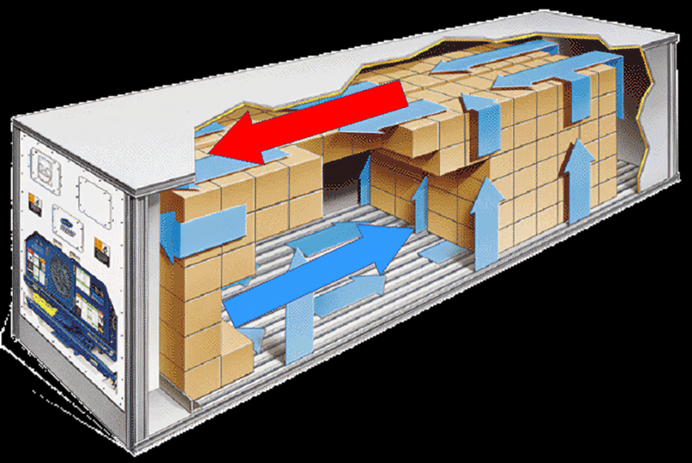

The working principle of a reefer container

The reefer container distributes cold air from the floor through a T-shaped deck. Therefore, they are also referred to as "bottom air conveying devices". This design ensures that the container generates stable air flow, which is sufficient to maintain the required temperature during transportation even under the most severe conditions. Regardless of the outdoor temperature, the reefer containers can provide a warmer temperature. Their temperature range is -35 degrees Celsius to 35 degrees Celsius. The cost of manufacturing reefer containers is about six times higher than traditional containers because they are equipped with additional insulation and independently powered refrigeration and heating devices.

Types of reefer containers

There are currently different types of reefer containers on the market. We can choose one based on energy efficiency, type of goods, and transportation requirements.

1. Closed reefer containers: This is a traditional integrated reefer container. It has an integral front wall and a fully electric automatic cooling and heating device.

2. Ventilated reefer containers: These are insulated containers with an air exchange system that can maintain a constant level of air inside the container through air exchange, balancing the oxygen level inside the container with the deterioration rate of the cargo.

3. Automatic Fresh Air Management (AFAM) reefer containers: This container adopts cutting-edge technology and automatically adjusts the air exchange inside the container to maintain a constant temperature. The working principle of AFAM reefer container is similar to that of MA/CA reefer container, which can control the composition of oxygen, carbon dioxide, and other gases. Regardless of external conditions, the control device can be adjusted to extend the shelf life of the goods.

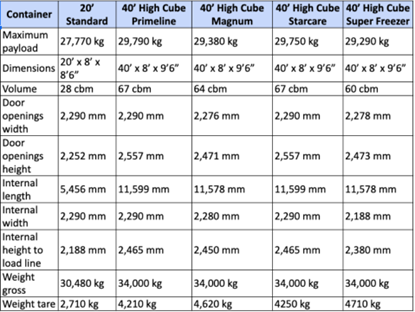

The size of the reefer containers may vary. The standards listed here are:

Goods suitable for transportation in reefer containers

Although reefer containers transport various goods, different products must be transported under different conditions to ensure freshness upon arrival. Goods suitable for refrigerated transportation are divided into three categories:

1. Frozen foods: including fresh fruits and vegetables, seafood, dairy products, eggs, candies, live plants, and flowers. They need a low temperature around freezing point, but they cannot be frozen. Their freshness and shelf life largely depend on their properties and surrounding conditions. The temperature setting of such products must consider the transportation stage of crops. They must be transported in the most precise way to maintain their commercial value. For example, asparagus and broccoli have a high respiratory rate, which releases a large amount of gas and water. They require the optimal temperature and humidity levels so that their quality and shelf life are not affected.

2. Frozen goods: refer to goods that need to be stored and transported at temperatures of -20 ℃ and below, i.e. they are frozen solids. Ice cream, frozen meat, poultry and seafood, concentrates, and pre made foods are some examples. The freezing temperature can prevent spoilage and help preserve flavor, aroma, texture, and quality. They can prevent the growth of pathogenic bacteria and microorganisms, while also slowing down enzyme activity and oxidation. For such goods, the refrigerated box must maintain the freezing temperature without fluctuations. Repeated freezing and thawing can lead to product paste.

3. Special and miscellaneous goods: These goods are non-food products that require optimal temperature and humidity. The majority of such goods are drugs and pharmaceuticals. Tobacco, batteries, chemicals, and film also fall into this category. Usually, they have special handling instructions for packaging, loading, temperature and humidity control.

Precautions for refrigerated transportation:

·Tightly package the goods and ensure their stability

·Set the reefer container to the specified temperature and humidity settings

·If necessary, pre cool the goods to ensure appropriate ventilation and correct settings

·Insure your goods as reefer containers may pose more risks compared to traditional containers.

CIMC Equilink provides various types of new and used containers, especially our standard containers, the price of 40HC and 20GP are very affordable. If you are looking for shipping containers for sale, please contact us by email or any other contact information.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文