-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

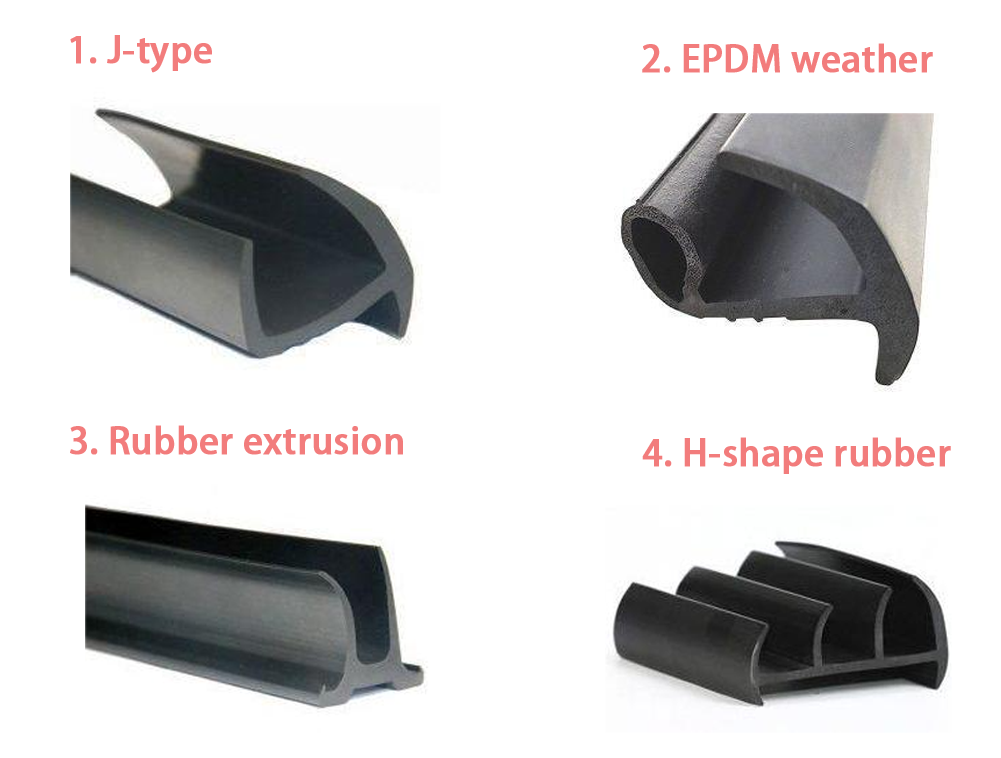

Container Parts4 Types of Shipping Container Door Seals StripsMar 01,2024This door seals strip also named container door gasket. Shipping container door seals are mainly working against water, snow, dust, or other contaminants, to protecting and sealing out the container. That is to say the shipping container door seals are the typical seal strip types used for weather stripping.

Continuous use of the shipping container door seals erodes the material gradually. As a result, it requires maintenance and replacement if necessary.

Shipping container door seals are made of high-quality rubber. It is a synthetic rubber primarily used for all outdoor applications. However, the specialty of this material is its outer membrane. It is an excellent air-tight and waterproof seal.

The application of the Shipping container Door Seals Strips

The shipping container door seal strips mainly be used for the following containers:

a. dry cargo containers 20 feet

b. dry cargo containers 40 feet& high

c. Refrigerated containers of 20 feet

d. Refrigerated containers of 40 feet

e. Tank steel shipping containers

Importance of installing shipping container Door Seals Strips

The shipping container door seals strips is vast for every cargo container. It is compulsory to install these container seals to prevent many obstacles from outside during the road. Installing shipping container door seals is necessary to keep the products safe inside. It mainly can be summarized as the following:

A. Flexibility

Shipping container door seals strips offer excellent flexibility for the container doors and edges. As a result, it becomes flexible while opening and closing the container door. Due to this flexibility, the cargo containers last longer than normal.

B. Prevent Leakage Against Water, Gas, or Air

Some shipping containers like tank steel shipping containers carry bulk liquids, gases, or powders, filling the gap between joints or openings will be a prime concern for this cargo container door. And this shipping container door seals strips can perfectly fill these gaps to prevent water, gas or Ail leak out.

Furthermore, it prevents liquids or gas from coming outside. Meanwhile, it also prevents outside contaminants from coming inside.

The types of the shipping container door seals strips

There are different types of shipping container door seals strips with various strips sizes and shapes.

a. J-type container door seal

This shape of container door seal is the most common in every cargo container. This shipping container door seal’s cross section resembles the English letter “J.” This rubber seal can withstand high loads of up to 10 MPa. Besides, it can alsowithstand incredibly high and low temperatures ranging from -40 °F to 248 °F (-40 °C to 120°C).

b. EPDM weather strip for container edge

This type of EPDM seal strip is explicitly designed for the edges of cargo containers. It is round with a hole at the lower part of the seal strips. The high-quality EPDM material is waterproof and can also withstand mild acids. Due to its excellent compressibility, the EPDM weather strip ensures better long-lasting.

c. Rubber extrusion strip for container door

This shipping container door seal has a U shape at the upper section and a flat surface at the bottom. Similar to the above seal strips, this type of rubber seal is also made of rubber. This type of seal strip is ideal for installation at the container doors.

d. H shape rubber seal strip for container door

This seal shape usually comes as H shape rubber seals, which can withstand high loads and temperatures. Like the other shipping container door seal discussed above, this seal strip is also made of high-quality EPDM rubber. Therefore, it can work against mild acids, too. This type of seal strip is ideal for sealing shipping container doors.

How to choose the proper shipping container door seals strips

Choosing a suitable sealing strip requires consideration from multiple aspects, such as the material, size, color, and viscosity of the sealing strip. These factors may all affect the performance and effectiveness of the sealing strip. Here are some suggestions to help you better choose the sealing strip that suits your needs.

a. Choose materials based on usage environment and requirements

b. Consider size and length

Choose the appropriate sealing strip based on the width and length of the gap. Generally speaking, the length of the sealing strip should be slightly longer than the gap to ensure that it can fully fill the gap

c. Considering stickiness and durability:

High quality sealing strips should have strong stickiness that can tightly adhere to the surface, preventing the entry of wind, rain, dust, etc. Meanwhile, stickiness also needs to be long-lasting to ensure long-term effectiveness.

d. Brand reputation

Choosing sealing strip products from well-known brands and good reputation can help you use them with more confidence.

Choosing the right shipping container door seals strips is an investment in the security and longevity of your cargo. At CIMC Intermodal Equilink Co., Ltd.("CIMC Equilink"), we take pride in delivering superior quality products that stand up to the toughest challenges. Explore our range of container shipping container door seals strips and experience the difference in quality for yourself.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文