-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

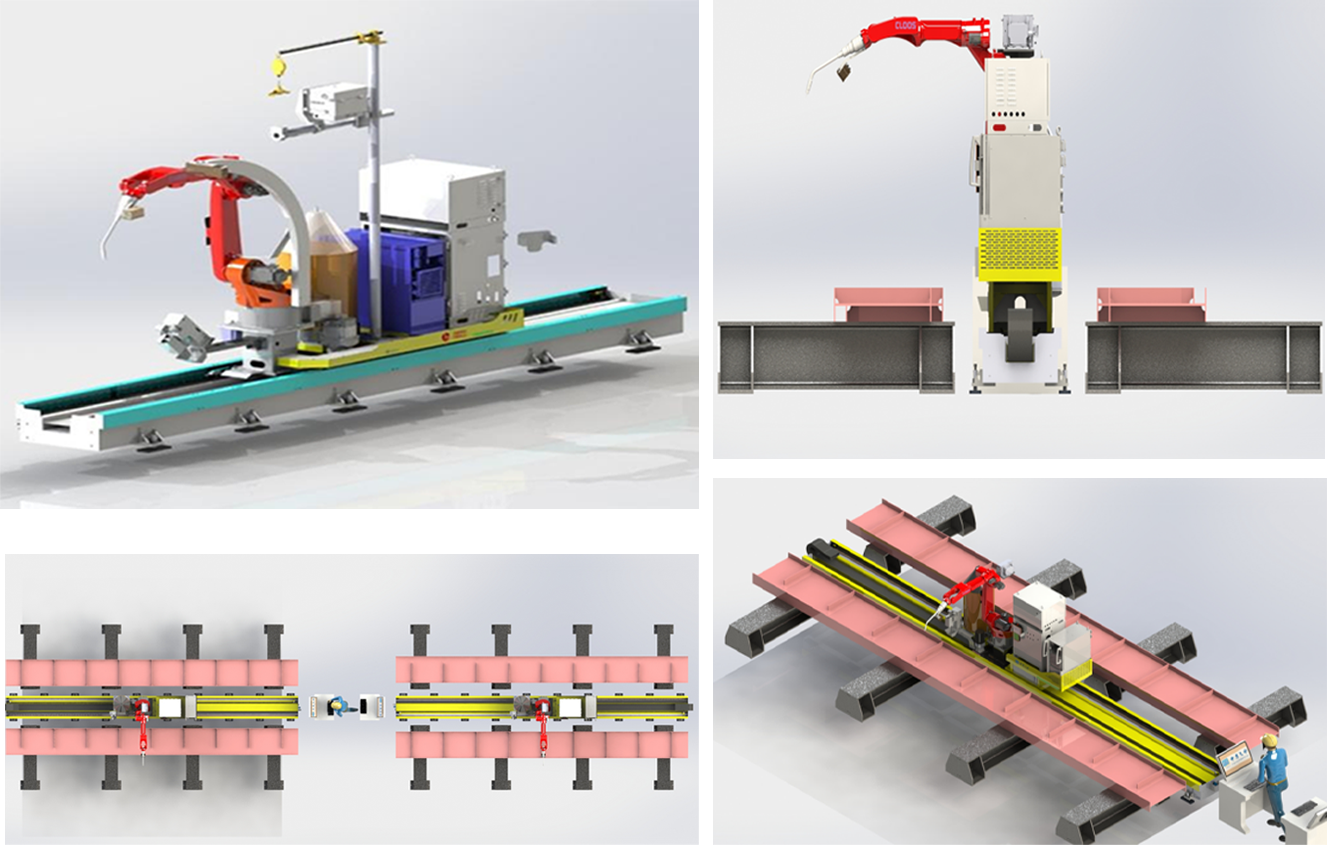

PromotionsCIMC FSAI 11-meter ground track vertical type (7-axis) robot welding workstationMar 29,2024Robot welding workstations represent a paradigm shift in welding technology, offering unmatched precision, productivity, and versatility in manufacturing operations. As industries continue to embrace automation to stay competitive in today's dynamic market, robot welding workstations emerge as indispensable tools for achieving higher efficiency, quality, and safety standards.

Equipment performance introduction

Equipment floorage:3000mm(W)x13000mm(L)

Effective welding area:1200mm(w)x11000mm(l)x600mm(h)

Visual Sensors: With a 3D line scanner that has a 1.5-m scanning area (Coarse positioning), 3D geometric vision (Precise positioning)

Welding station: Dual workstation for welding on the left and right sides of the track. A/B workstation waits for material welding conversion, reducing auxiliary time.

Welding Mode:① photography-driven reverse modeling, drawing-free & model-free

② BIM model driving welding

Applicable workpiece: Portal steel frame, H-beam & Web stiffener, crane beam, steel platform, steel beam on roof, box column ( The Partial Joint Penetration,PJP & The Complete Joint Penetration ,CJP), beam/column end plate CJP

Welding plate thickness:5mm~50mm

Welding range: flat position welding, vertical position welding(automatic wrap the corners), multi-layer & multi-pass weld, PJP

Welding conditions:80%Ar+20%CO2; 1.2mm Solid wire

Scanning time: Coarse positioning scanning time of 10 seconds, precise positioning scanning time of 1.5 seconds per node.

Welding prep time: Using the example of a 9-meter crane beam with 11 stiffeners, it takes about 4 minutes to prepare and lift a single workpiece, and about 7 minutes (including scanning time) to prepare and lift two workpieces.

Box column welding: Drawing-free & Model-free, Large scale scanner will automaticly plan welding path and parameters (The Complete Joint Penetration , CJP) .

Technology 1: Line scan 3D camera: Femostar

Technology 2: 3D area scan camera Femocam G3

Technology 3: Intelligent welding system Fesinweld V3.0

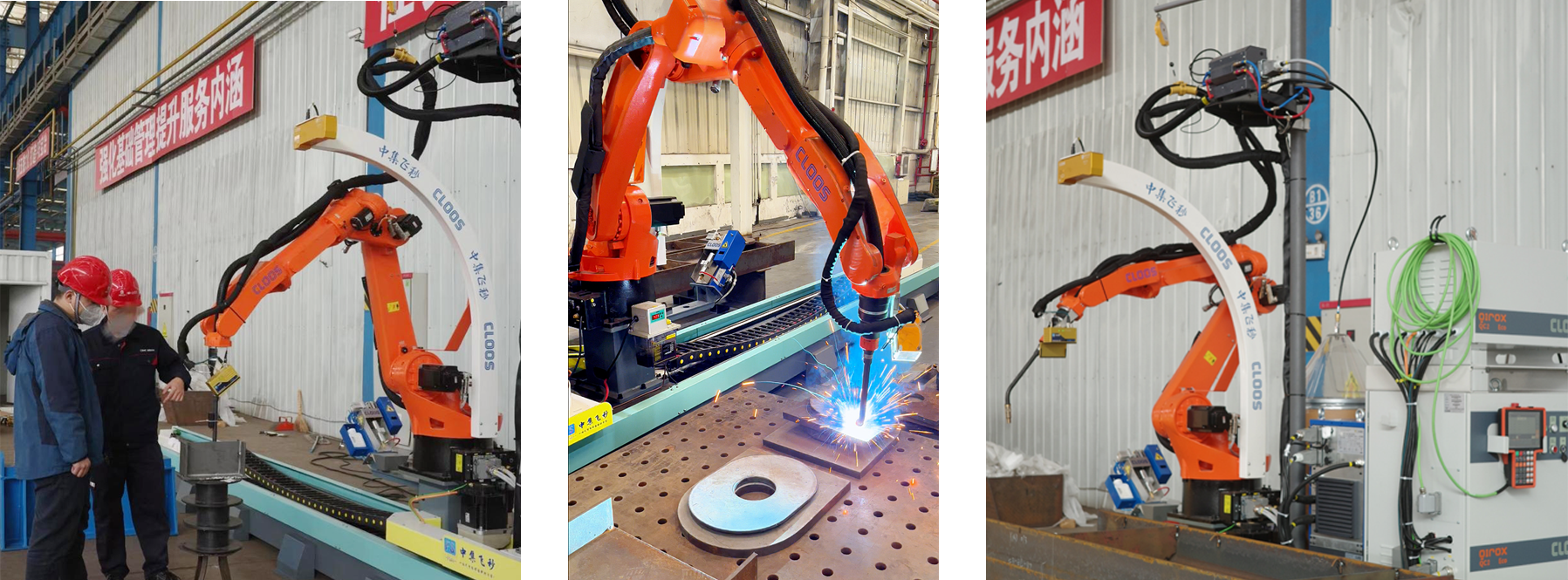

Physical display pictures:

At CIMC Intermodal Equilink Co., Ltd.("CIMC Equilink"), we're committed to providing cutting-edge automation solutions that empower manufacturers to thrive in the age of Industry 4.0. Explore our range of robot welding workstations and unlock the full potential of automated welding in your production processes.

Prev article: No Data Next article: No DataQuick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文