-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistics Tools

ContainersHow Shipping Containers Are MadeMay 09,2024Shipping containers have become ubiquitous in global trade, serving as the backbone of modern logistics and transportation. From carrying goods across oceans to repurposing them into innovative living spaces, the versatility of shipping containers knows no bounds. Have you ever wondered how these durable containers are made? In this blog post, we'll take you behind the scenes and explore the fascinating process of crafting shipping containers from start to finish.

1. Design Phase:

The journey of a shipping container begins with meticulous design. Engineers consider various factors like size, weight capacity, durability, and material choice, using CAD (Computer-Aided Design) software aids in creating precise blueprints, ensuring the container meets international standards and regulations. Standard shipping containers typically adhere to ISO (International Organization for Standardization) standards, ensuring compatibility across global transportation networks.

2. Material Selection:

High-grade steel is the primary material for manufacturing shipping containers due to its strength, durability, and resistance to corrosion. Manufacturers procure large rolls or sheets of steel, which undergo stringent quality checks to meet industry standards.

3. Fabrication:

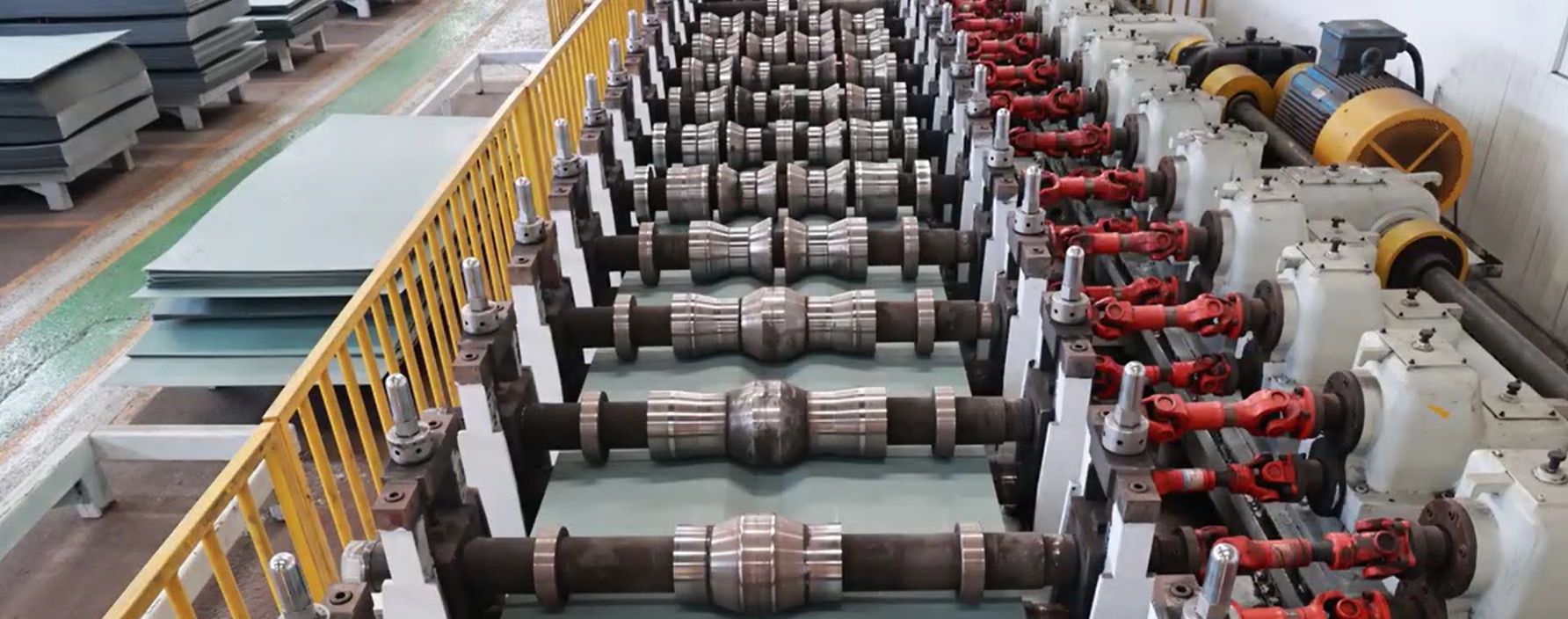

The fabrication process starts with cutting the steel sheets into precise dimensions using industrial cutting machines. These cut pieces then move to welding stations where skilled welders assemble them into the familiar rectangular box shape. Advanced welding techniques ensure sturdy joints to withstand the rigors of transportation.

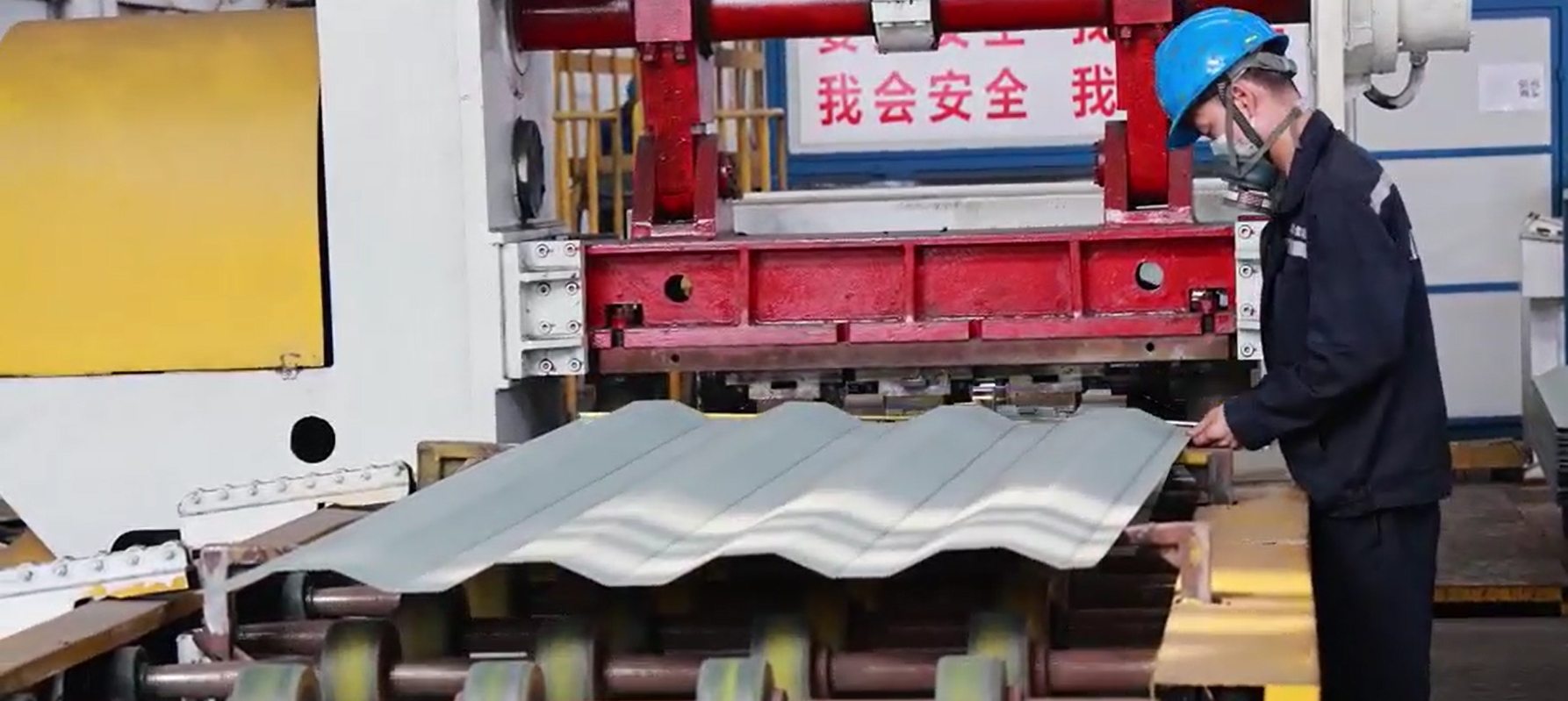

4. Corrugation:

To enhance structural integrity, the walls of the container undergo corrugation, a process where grooves are pressed into the steel sheets. This corrugation adds strength while minimizing weight, making the container more efficient for transportation.

5. Frame Assembly:

The container's frame, typically made of steel beams, is fabricated separately. This frame provides crucial support and rigidity to the container, ensuring it can withstand the stresses of transportation and stacking

6. Floor Assembly:

The container's floor is constructed separately before being welded to the main structure. It typically consists of steel cross members and a plywood or bamboo flooring, providing a stable surface for cargo while remaining lightweight.

7. Doors and Fittings:

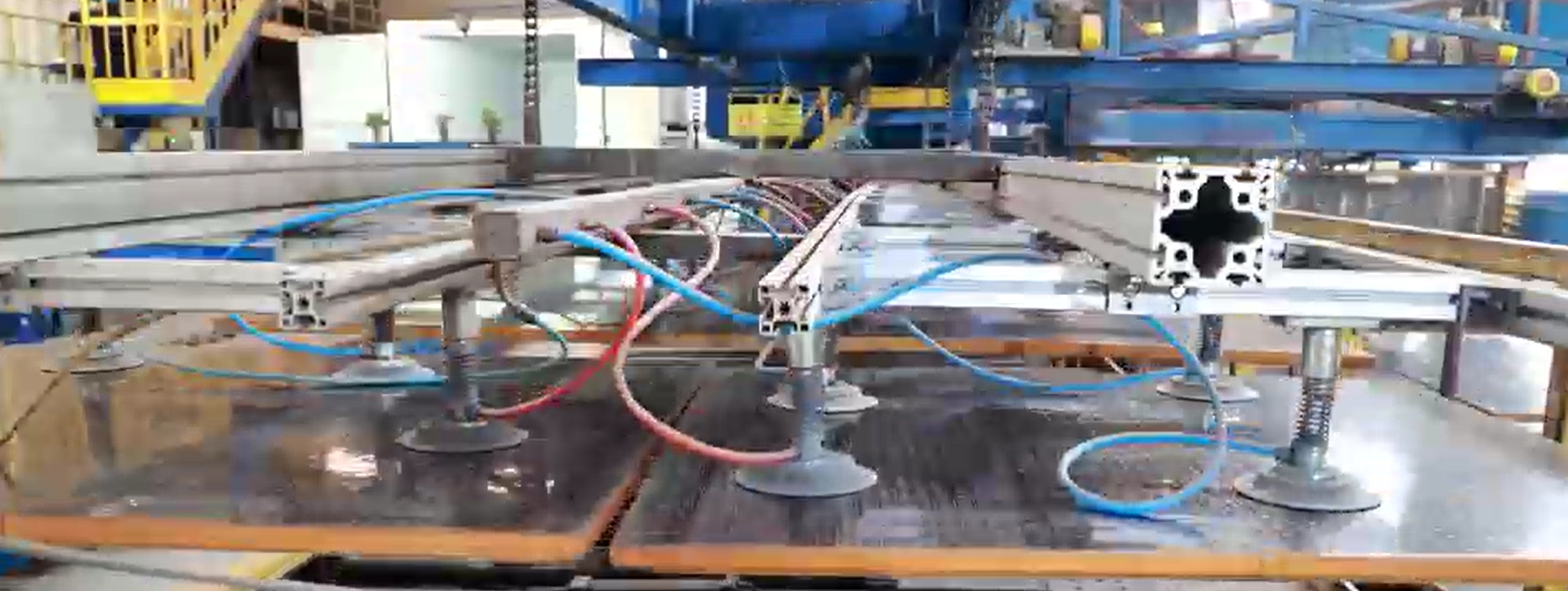

Once the main body is assembled, attention turns to installing doors and fittings. Heavy-duty doors with locking mechanisms are fitted into one end of the container, allowing easy access for loading and unloading. Other fittings, such as ventilation ducts, drainage holes, and securing points, are also added based on customer specifications.

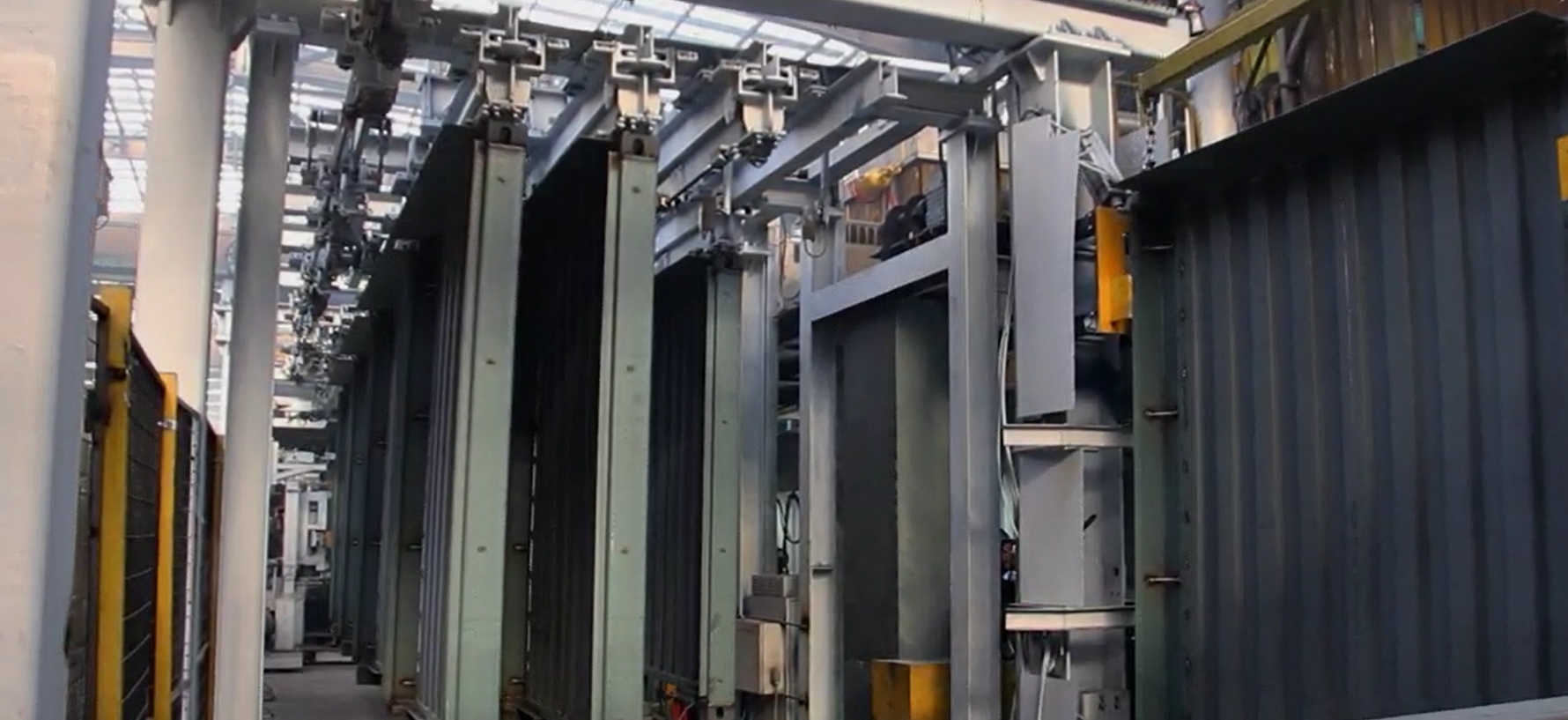

8. Painting and Coating:

To protect against corrosion and enhance aesthetics, the container undergoes painting or coating processes. A primer coat is applied first, followed by layers of weather-resistant paint or specialized coatings. Some containers may also receive branding or markings per customer requirements.

9. Quality Assurance:

Throughout the manufacturing process, quality control checks are conducted at various stages to ensure adherence to standards and specifications. Inspections cover weld quality, dimensional accuracy, paint thickness, and structural integrity.

10. Final Inspection and Testing:

Before leaving the factory, each shipping container undergoes a final inspection and testing phase. This may involve pressure testing for watertightness, load testing for structural strength, and functionality checks for doors and other components.

Crafting shipping containers is a meticulous process that requires precision, expertise, and attention to detail at every step. At ClMC Intermodal Equilink Co., Ltd.("ClMC Equilink"), we take pride in our commitment to quality craftsmanship and excellence in container manufacturing. Whether you need standard shipping containers for transporting goods or customized containers for innovative projects, you can trust us to deliver reliable solutions tailored to your needs. Contact us today to learn more about our container offerings and how we can assist you with your shipping and storage requirements.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文