-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

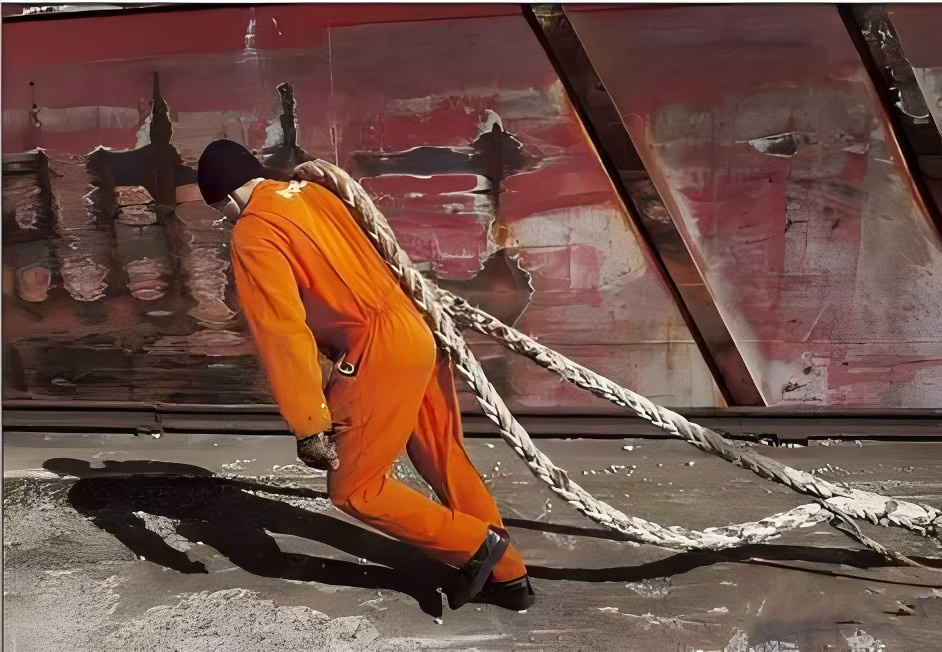

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistics Tools

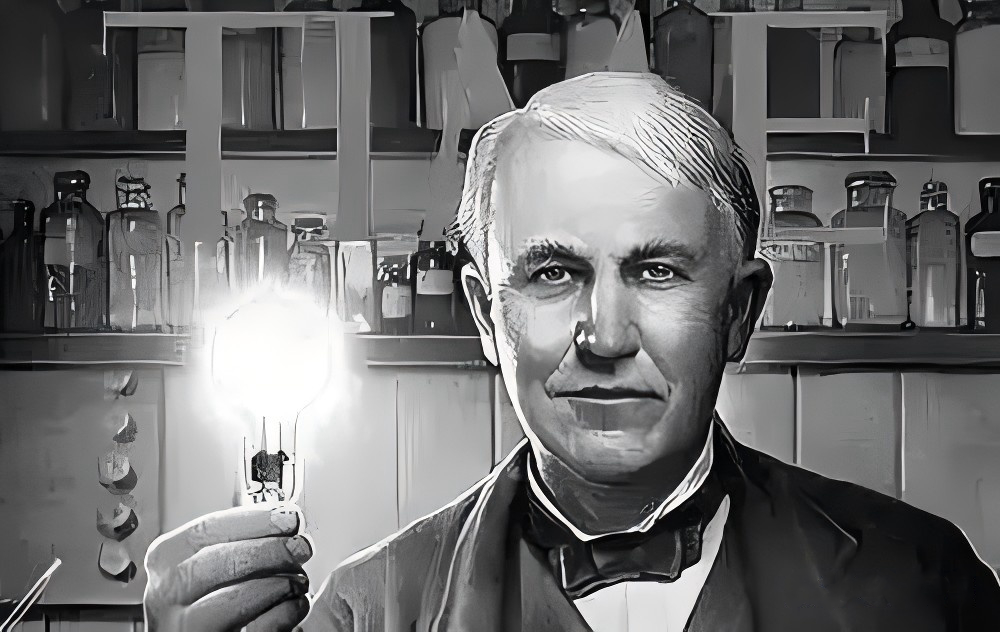

ContainersMalcolm McLean: The Father of ContainersSep 06,2024Malcolm McLean, born in 1913 in Maxton, North Carolina, is often hailed as the father of containers in the U.S. However, while McLean revolutionized the industry, he wasn’t the first to invent containers. In fact, as early as 1850, British railways were using freight carriages, and American railways were also experimenting with container transport. The British even tried palletized shipping in the early 20th century. So, what made McLean earn the title "Father of Containers"?

In 1931, McLean bought a truck to start his transport business during a fiercely competitive time in the U.S. trucking industry. He found ways to cut costs, like converting his gasoline engine to diesel and frequenting the same gas stations for discounts. But his real frustration came when he had to wait hours, sometimes days, at the docks to load and unload goods. The docks were chaotic, with goods scattered everywhere, and the process was slow and costly. It sparked an idea—why not build a system where cargo could be loaded directly onto ships in large boxes? The Beginning: A Truck and a Big Idea

The Beginning: A Truck and a Big Idea

By this time, McLean's trucking business had grown into the third-largest in the U.S. Instead of just dreaming, he took action. He built his own dock and bought a small oil shipping company, Pan-Atlantic, modifying ships to carry large metal boxes. McLean realized that reducing shipping costs meant looking beyond just the containers. Ports, cargo ships, cranes, trucks, and even the way shippers operated all impacted overall costs.

McLean's first big experiment involved shipping beer. He compared traditional bulk shipping to using containers. The result? A 95% reduction in costs, bringing the freight price of beer down from 20 cents to just 4 cents. The massive cost savings meant massive business potential. A Bold Experiment

A Bold Experiment

However, there were hurdles. Goods varied in size, making it tough to fill containers efficiently. Containers were often returned empty, and sometimes even lost at the docks. Despite the initial challenges, McLean kept pushing forward.

The Vietnam War: A Turning Point

The Vietnam War in 1967 was a game-changer for McLean. The U.S. government needed to transport huge volumes of supplies to Asia and demanded maximum efficiency. Enter McLean's containers. This was when the 3C principle was born: each container could only carry one type of cargo and go to one destination. The sheer volume of government orders made 3C feasible. By the end of the war, McLean had netted $450 million, ushering in a boom period for container shipping.

After the war, McLean's fleet grew to 31 container ships, and the industry exploded. By 1974, the U.S. and Europe had over a million containers in circulation, increasing the shipping capacity nearly 20-fold. Competition intensified, and shipping giants emerged, driving down prices and forcing companies to scale up to survive. This led to a concentration of power in the hands of fewer, larger companies, which in turn helped standardize containers globally. Containers Revolutionize the World

Containers Revolutionize the World

Once standardized, containers revolutionized the shipping industry. Trucks, trains, ports, and ships across the world became compatible with one another, allowing goods to be transported seamlessly across different modes of transport. Cranes became the primary tool for handling containers, loading and unloading them with unprecedented speed and efficiency. With standardized containers, costs plummeted, and the shipping process became faster than ever.

As shipping became more efficient, factories no longer needed to be near docks, and workers didn’t need to live in port cities. This increased efficiency did, however, lead to large-scale unemployment in traditional dock work. Port jobs, once abundant and crucial, became fewer as cranes took over much of the labor. To combat the initial resistance from dock workers, companies offered compensation to gain their cooperation. A Global Shift in Labor and Manufacturing

A Global Shift in Labor and Manufacturing

The rise of container shipping also sparked a global division of labor. Products like mobile phones, cameras, and electronics started being manufactured across multiple countries. Components might be made in Japan or South Korea, antennas in China, and final assembly in Malaysia. Thanks to containers, shipping costs dropped, fueling globalization and transforming the world into a vast interconnected factory.

Containers, though simple in design, had a profound impact on global productivity, changing manufacturing and shipping on a massive scale. What McLean recognized was that innovation isn't always about inventing something entirely new—it’s about creating a system where that innovation can thrive. McLean's container system revolutionized shipping, but it was the supporting infrastructure of ports, cranes, and logistics that allowed it to succeed. The Impact of Containers

The Impact of Containers

McLean’s journey wasn’t without failure. Despite his early success, he eventually went bankrupt due to intense competition and massive debt. Still, McLean’s contributions to the shipping industry have left a lasting legacy. Even though he didn’t technically "invent" the container, he made it work in a way that changed the world forever, and that's why we honor him as the "Father of Containers."

CIMC Equilink pays homage to Malcolm McLean’s legacy by offering top-quality shipping containers and container parts. If you're looking for containers to meet your shipping needs, reach out to us at info.equilink@cimc.com or request a quick quote. We're here to help you navigate the world of containerization just like McLean did! His innovation proves that sometimes, the simplest ideas—when executed on a large scale—can transform industries and change the course of history.

His innovation proves that sometimes, the simplest ideas—when executed on a large scale—can transform industries and change the course of history.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文