-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

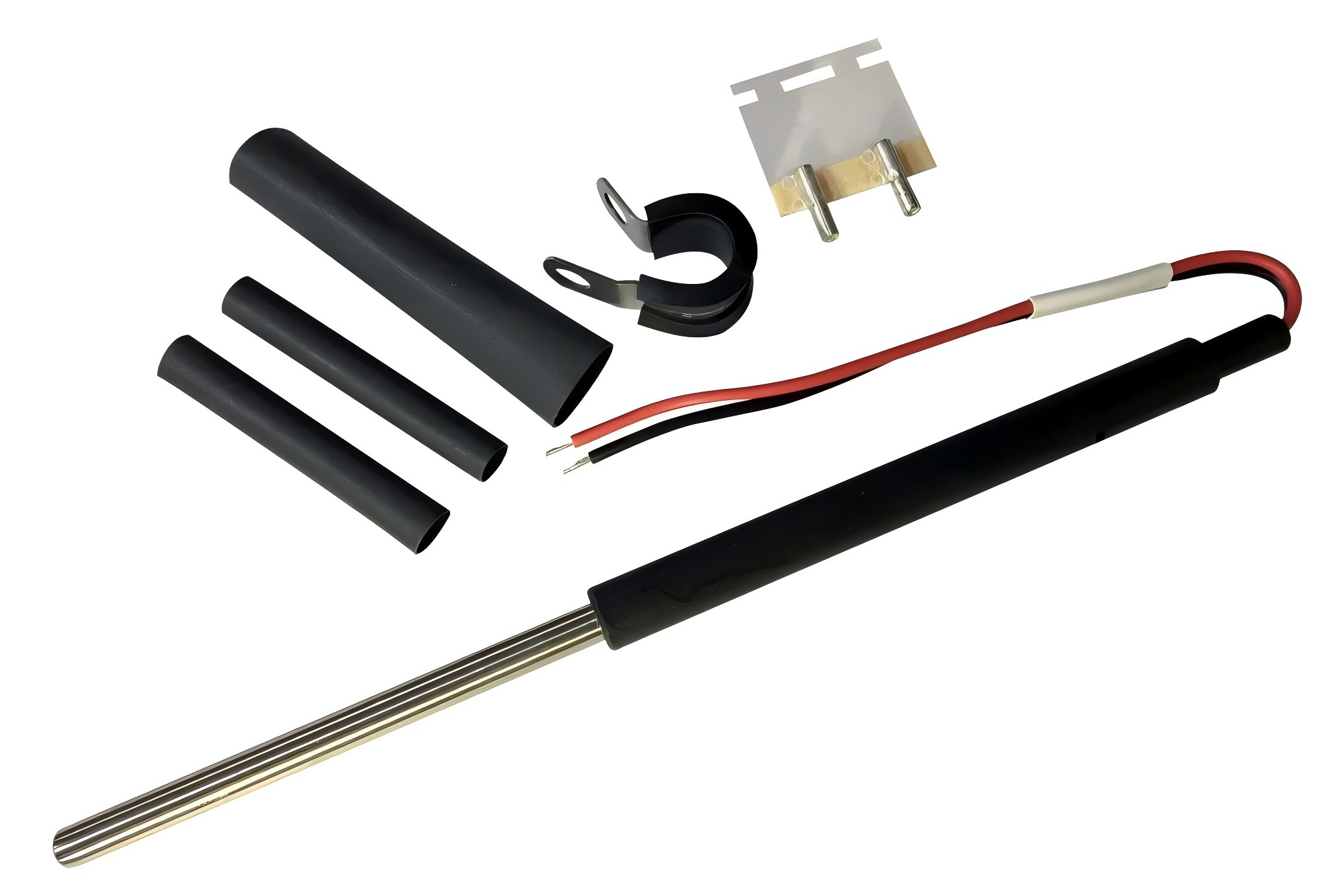

Container PartsReefer Unit Parts (6) - Temperature SensorsApr 08,2025In refrigerated shipping containers, maintaining optimal cargo conditions hinges on accurate temperature monitoring. The reefer units - temperature sensor serves as the eyes of the reefer system, providing real-time data critical for preserving perishable goods. Understanding its specifications and performance ensures operators can select components that deliver reliability in even the most demanding environments.

Key Specifications for Reefer Temperature Sensors

- Operating Range: Withstands -55°C to 80°C, ensuring functionality in Arctic cold and tropical heat, while the ambient range of -58°F to 176°F caters to global logistics standards.

- Low Power Dissipation: Just 10 milliwatts minimizes energy draw, ideal for off-grid or battery-powered reefer units.

- Dielectric Strength: 1000V RMS at 60Hz with ≤0.75mA leakage current between case and leads ensures electrical safety and resistance to voltage surges.

- Conductor Design: 20 AWG stranded tinned copper wire (300V rating) enhances flexibility, corrosion resistance, and long-term connectivity in humid or salty environments.

A malfunctioning reefer units - temperature sensor can lead to misregulated cooling, cargo spoilage, or unnecessary energy waste. High-quality sensors undergo rigorous testing, such as IP67 ingress protection and compliance with ISO 14526 for marine refrigeration, to ensure stability across vibration, moisture, and temperature fluctuations. Their precision directly impacts alarm systems, defrost cycles, and compressor efficiency, making them a cornerstone of reefer reliability.

Selecting the Right Temperature Sensor for Your Reefer

Operators should prioritize sensors with wide temperature tolerances for cross-climate journeys and robust insulation to prevent signal interference. Tinned copper conductors are essential for coastal routes, resisting salt corrosion, while low power consumption is critical for units relying on generator or solar power. Always verify calibration standards and compatibility with your reefer’s control system.

Elevate Reefer Monitoring with CIMC Equilink

For trusted reefer units - temperature sensors, CIMC Equilink offers advanced solutions engineered to meet the highest industry benchmarks. Their sensors feature extended temperature ranges, minimal power draw, and rugged construction, ensuring accurate readings in extreme conditions. Backed by rigorous testing for dielectric strength and environmental resistance, CIMC Equilink’s sensors deliver unmatched precision, reducing operational risks and safeguarding cargo integrity.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文