-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

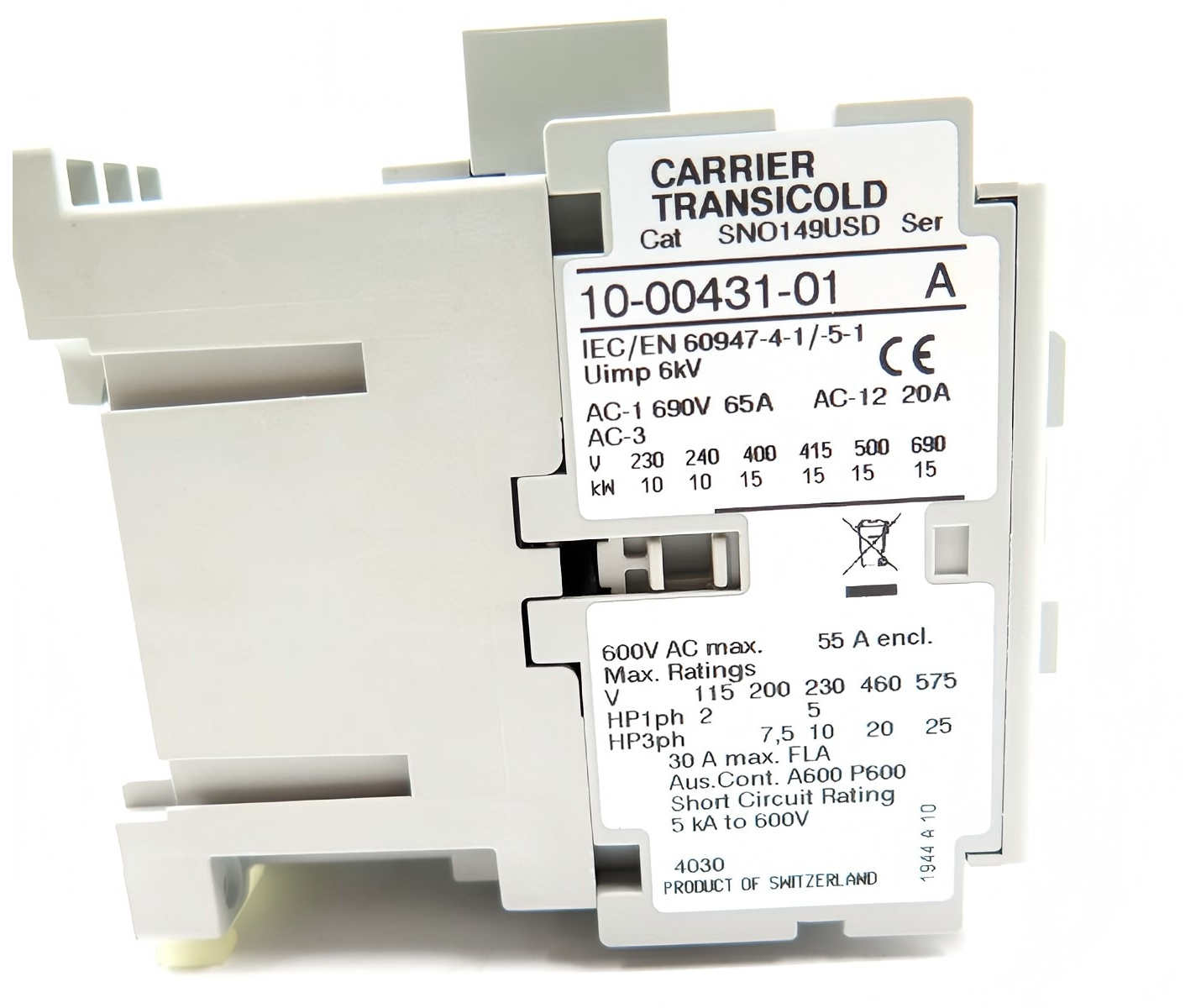

Container PartsReefer Unit Parts (8) - 4 Pole ContactorsApr 08,2025In refrigerated shipping containers, precise electrical switching is essential for maintaining optimal cooling system performance, and the reefer units - 4 pole contactor serves as a cornerstone of this functionality. Designed to manage high-power circuits with reliability, these components play a critical role in controlling compressor, fan, and heater operations across diverse environmental conditions.

Key Specifications for 4 Pole Contactors

- Type & Configuration: A 4-pole design featuring 3 normally open (NO) and 1 normally closed (NC) contacts, enabling simultaneous control of multiple circuits of varying loads.

- Electrical Ratings: Rated for 30A at 600VAC, ensuring compatibility with standard reefer unit power systems. The 20/24V 50/60Hz coil with Class H insulation (180°C rating) delivers stable operation even under prolonged use.

- Environmental Resilience: Operates reliably in ambient temperatures ranging from -40°F to 185°F (-40°C to 85°C), making it suitable for extreme cold or tropical logistics. Copper alloy terminal bases enhance conductivity and resist corrosion in harsh maritime environments.

- Efficiency: A coil rated current of 0.51A ±0.06A minimizes energy draw, contributing to overall reefer unit efficiency.

Why Contactors Matter in Reefer Systems

A malfunctioning reefer units - 4 pole contactor can lead to erratic system behavior, motor damage, or even complete shutdowns—risks that threaten cargo integrity and operational costs. High-quality contactors with robust arc suppression and silver-alloy contacts reduce wear and ensure long-lasting performance, while Class H insulation prevents thermal breakdown in high-heat scenarios.

Selecting the Right 4 Pole Contactor for Your Reefer

Operators should prioritize compatibility with their reefer’s voltage requirements, load specifications, and environmental exposure. Look for units compliant with IEC 60947-4-1 for industrial control devices and IP20 protection against solid debris. For global fleets, wide temperature ratings and corrosion-resistant materials like copper alloy terminals are non-negotiable.

Elevate Reefer System Reliability with CIMC Equilink

When precision and durability are paramount, CIMC Equilink’s reefer units - 4 pole contactors deliver unmatched performance. Engineered to meet the strictest specifications—including Class H insulation, wide temperature tolerance, and rugged copper alloy construction—these contactors ensure seamless circuit control in even the most demanding reefer environments. Backed by industry certifications and rigorous testing, CIMC Equilink’s solutions minimize downtime, enhance safety, and optimize energy efficiency, making them the trusted choice for cold chain professionals worldwide.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文