-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistics Tools

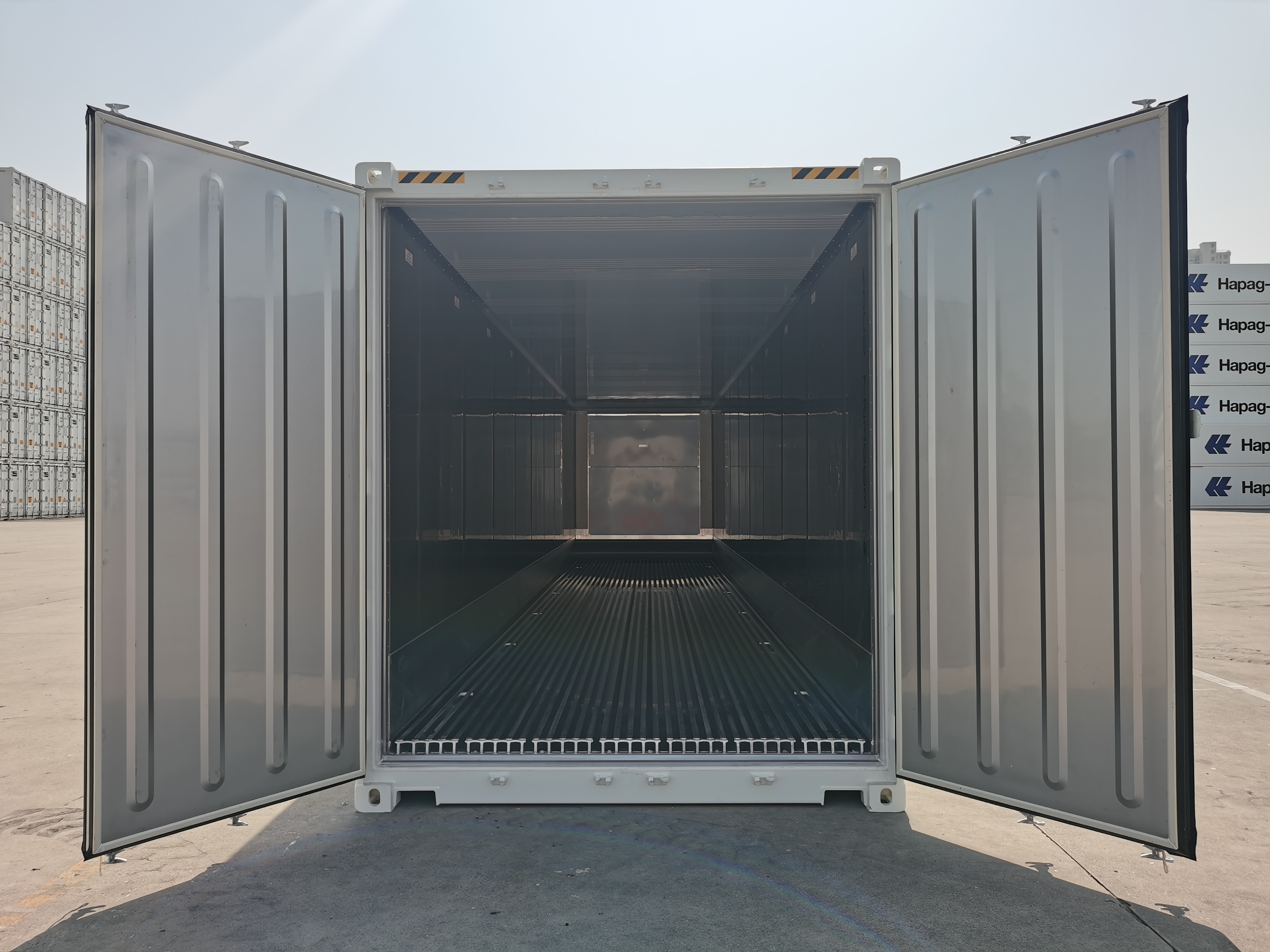

ContainersReefer Shipping Containers(1) - Size Selection FactorsApr 25,2025Choosing the right reefer shipping containers is critical for optimizing temperature-controlled logistics and preserving perishable cargo. When deciding between 20-foot and 40-foot freezers, three factors dominate: volume, load capacity, and transportation scenarios. Here’s a detailed breakdown to guide your decision.

1. Volume: Matching Cargo Size

20-foot reefers offer a compact solution with internal capacities of 27–28.3 m³ (953–999 cu ft), ideal for moderate shipments like pharmaceuticals, dairy products, or small-batch produce. Their smaller footprint suits lightweight but dense cargo, ensuring efficient space utilization. In contrast, 40-foot reefers double the volume to 58–67.3 m³ (2,048–2,380 cu ft), making them indispensable for bulk loads such as frozen meat, fruits, or textiles. The 40-foot high-cube variant adds height for voluminous goods, accommodating up to 23 EUR pallets.

2. Load: Balancing Weight and Efficiency

While 20-foot reefers have a lower tare weight (2,300–3,050 kg), they excel at handling heavier payloads (21,450–27,430 kg), making them suitable for machinery parts or steel coils. Their payload-to-weight ratio ensures cost-effective transport for dense cargo. Conversely, 40-foot reefers carry slightly higher payloads (27,600–29,580 kg) but prioritize volume over weight, optimizing costs for bulk shipments. Note that 40-foot units may incur higher transport fees due to their larger size, though economies of scale often offset this for large loads.

3. Transportation Scenarios: Adapting to Routes

Short Hauls & Limited Access: 20-foot reefers thrive in urban or narrow routes, fitting seamlessly into trucks and railcars with minimal maneuvering challenges. Their agility is crucial for time-sensitive deliveries in crowded markets.

Long-Distance & Intermodal Moves: 40-foot reefers dominate international shipping, leveraging container ships’ power supply systems to maintain temperatures from -25°C to +30°C during extended voyages. Their compatibility with global standards ensures smooth transitions across Sea, rail, and road networks.

Final Considerations

Both sizes integrate advanced features like insulated panels, forced-air circulation, and digital temperature monitoring to safeguard cargo integrity. For instance, modern reefers use R134a refrigerant and GPS-enabled tracking to meet strict cold chain requirements.

Why CIMC Equilink’s Reefer Shipping Containers Stand Out

When investing in reefer solutions, CIMC Equilink’s products deliver unmatched reliability. Their 20-foot and 40-foot reefers feature aluminum exteriors to prevent corrosion, stainless steel interiors for food-grade safety, and -30°C to +30°C temperature control. Rigorously tested through a 12-point inspection, these containers ensure compliance with ISO, CSC, and UIC standards, making them ideal for global logistics. Whether you need a compact 20-foot unit for local distribution or a high-cube 40-foot freezer for intercontinental shipments, CIMC Equilink’s reefers combine durability, energy efficiency, and precision climate control to protect your cargo from farm to market.

By aligning your choice with volume, load, and transportation needs, you can unlock the full potential of reefer shipping containers while minimizing costs and maximizing freshness.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文