-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

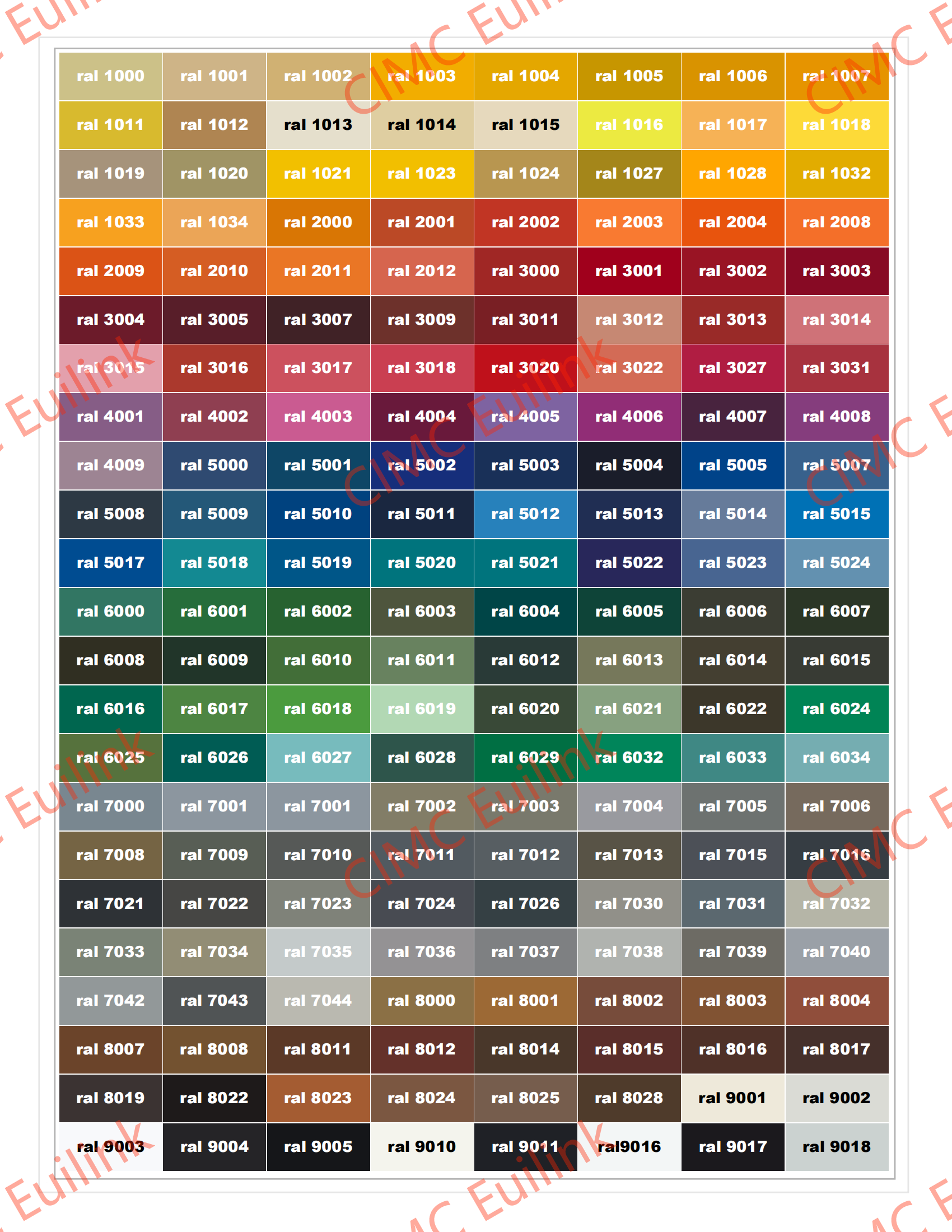

Container CoatingShipping Container Coating (4) - Color Codes ExplanationMar 13,2025Shipping container coatings are not just about protection—they’re also a visual language that communicates identity, safety, and compliance across global supply chains. From standardized hues like RAL 5010 blue to custom corporate colors and high-visibility safety shades, the choice of shipping container coating color codes plays a critical role in branding, logistics efficiency, and regulatory adherence. This article explores the importance of color in container coatings, key industry standards, and how advanced formulations ensure vibrant, long-lasting finishes even in harsh marine environments.

Why Color Matters in Shipping Container Coatings

- Branding and Identification: Unique colors help operators differentiate their fleets, streamline inventory tracking, and reinforce brand recognition.

- Safety Compliance: High-visibility colors like yellow or orange are mandated for containers transporting hazardous materials, ensuring clear warnings for handlers and inspectors.

- Asset Management: Consistent color codes simplify maintenance scheduling, as repainting mismatched containers can signal damage or wear.

Key Color Standards for Shipping Container Coatings

1. RAL 5010 Blue: The Industry Benchmark

RAL 5010, a deep sky blue, is the most widely used color code for shipping container coatings. It originated from the International Organization for Standardization (ISO) to standardize container appearance for global trade. Key advantages include:

Visibility: Easily distinguishable in ports and yards, reducing handling errors.

Corrosion Resistance: Typically paired with epoxy or acrylic coatings to withstand saltwater exposure.

Regulatory Compliance: Meets ISO 6346 requirements for container identification.

2. Custom Colors for Branding

Many operators opt for custom shipping container coating colors to align with corporate branding or regional preferences. These may include:

Metallic Finishes: Enhancing aesthetics for high-value cargo or luxury goods containers.

Matte or Gloss Textures: Balancing visual appeal with ease of cleaning.

UV-Resistant Pigments: Preventing fading in sunny regions like the Middle East or Australia.

3. Safety-Critical Colors

For containers carrying dangerous goods (DG), specific shipping container coating colors are mandated by the IMDG Code:

Yellow: Indicates flammable or explosive materials.

Red: Signifies oxidizing substances or organic peroxides.

Orange: Highlights dangerous goods requiring special handling.

These colors are often paired with reflective stripes or hazard symbols for maximum visibility.

How Coatings Maintain Color Integrity in Harsh Conditions

Marine environments pose extreme challenges to shipping container coatings, including:

- UV Radiation: Leading to color fading and resin degradation.

- Saltwater Spray: Causing corrosion and blistering.

- Temperature Swings: Expanding and contracting the coating film.

- High-Quality Pigments: Incorporating inorganic or organic pigments with superior lightfastness.

- UV Stabilizers: Chemical additives that neutralize UV damage.

- Cross-Linked Resins: Enhancing film density to resist moisture penetration.

Choosing the Right Color and Coating for Your Needs

When selecting shipping container coating color codes:

- Assess Application Requirements: Exterior vs. interior, branding needs, and safety regulations.

- Evaluate Durability: Opt for coatings with proven resistance to your operational environment (e.g., coastal vs. inland).

- Partner with Experts: Work with suppliers offering color-matching services and compliance guidance.

Elevate Your Container’s Performance with CIMC Equilink

CIMC Equilink specializes in delivering shipping container coatings that blend color precision with industrial-grade durability. Their comprehensive color solutions include:

Standard RAL 5010 and Custom Hues: Ensuring brand consistency and regulatory compliance.

Safety-Critical Coatings: Engineered to meet IMDG and ISO standards.

Advanced Formulations: UV-stabilized acrylics and epoxy systems that retain color and protect containers in saltwater, sunlight, and extreme temperatures.

With a global network of experts, CIMC Equilink provides end-to-end support—from color matching to application guidance—to ensure containers look and perform their best, anywhere in the world.

Stay updated on the latest trends in shipping container coatings by subscribing to our blog. Connect with us to explore how color codes can elevate your container fleet’s efficiency and aesthetics.

Prev article: No Data Next article: Shipping Container Coating (3) - Efficient Global Delivery ApproachesQuick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文