-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistics Tools

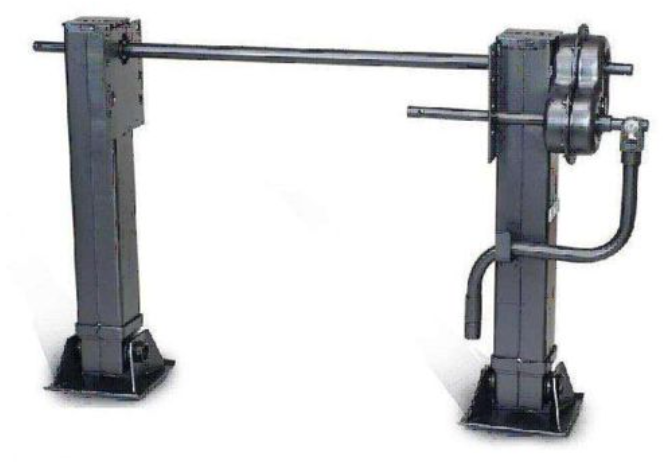

Vehicle Parts6 Common Types of Semi-Trailer Landing GearsJan 27,2026Looking for reliable trailer parts like trailer landing gear and trailer rims? Semi-trailer landing gears (commonly called “landing legs”) are indispensable components for semi-trailers—supporting the vehicle when separated from the tractor. With standard specs including a stroke of ~45cm, closed height of ~90cm, rated load of 28 tons, and static load of 40 tons, they vary in style and function to suit different scenarios. Below’s a detailed breakdown of 6 commonly used types.

1. Single-Acting Landing Gears

• Core Structure: Gear boxes on both left and right sides (available in built-in or external designs).

• Operation: Independent lifting/lowering via two cranks; equipped with high and low speed gears (low-speed gear required for load-bearing).

• Advantages: Strong adaptability—suitable for both flat and uneven ground; classic, reliable design.

• Application: Universal choice for most semi-trailer models, especially those operating in complex road conditions.

2. Linked Landing Gears

• Core Structure: One integrated gear box; controls left/right landing gears simultaneously via a single crank.

• Operation: High and low speed gears; upgraded from single-acting types for efficiency.

• Advantages: Lifting efficiency doubled compared to single-acting gears; simple, synchronized operation.

• Limitations: Only suitable for flat surfaces; requires cushion blocks to level the supporting surface on uneven ground.

• Application: Semi-trailers operating on paved roads or standardized logistics yards.

3. Aluminum Alloy Landing Gears

• Core Feature: Lightweight design (self-weight: ~30–40KG), mostly single-acting.

• Function: Same basic functionality as single-acting landing gears.

• Advantages: Nearly 50% lighter than traditional steel landing gears—ideal for weight-sensitive models.

• Limitations: Insufficient strength for frequent use; prone to damage with regular take-off/landing.

• Application: Semi-trailers that rarely detach from the tractor (low-frequency drop-and-hang scenarios).

4. Hydraulic Landing Gears

• Core Technology: Electromechanical-hydraulic integration; integrated micro-hydraulic system.

• Operation: Solenoid valve controls oil circuit direction (after reaching rated pressure) to extend/retract cylinders individually or simultaneously.

• Advantages: High automation; automatic balance within effective cylinder stroke—suitable for all road conditions; ideal for high-frequency, efficient drop-and-hang transportation.

• Limitations: Heavy self-weight; cost ~5x that of ordinary landing gears; limited maintenance points and high long-term maintenance costs—low market penetration.

5. Pneumatic Landing Gears

• Core Technology: Uses pressure from the vehicle-mounted gas cylinder (regulated to rated air pressure via automatic pressure relief valves); pneumatic solenoid valve controls air path direction.

• Operation: Cylinders hidden in the landing gear expand/contract individually or simultaneously—no crank or gear transmission.

• Advantages: High automation; automatic balance on all road conditions; no manual crank required (high lifting efficiency); lighter than hydraulic types; no oil leakage risk—suitable for efficient drop-and-hang transport.

• Limitations: Limited maintenance points (same challenge as hydraulic landing gears).

6. Pneumatic-Hydraulic Combined Landing Gears

• Core Design: Combines the high no-load speed of pneumatic landing gears with the stable load-bearing lifting of hydraulic types.

• Advantages: Higher lifting efficiency than single hydraulic/pneumatic designs.

• Limitations: Immature technology and complex structure (higher failure rate); lack of industry standards and policy norms—facing the same market challenges as hydraulic/pneumatic types.

The Trend: From Traditional Manufacturing to Intelligent Transformation

These trailer landing gear types reflect the semi-trailer industry’s shift toward intelligence. This transformation enhances operational safety, improves efficiency and product quality, and boosts the overall competitiveness of the logistics sector.

Our Full Range of Trailer Parts

CIMC Equilink provides a comprehensive lineup of trailer parts, including:

• Core components: Trailer landing gear, trailer rims.

• Supporting parts: Trailer brake drums, trailer axles, etc.

Our professional vehicle parts team ensures reliable quality and tailored solutions for your needs.

Get Your Trailer Landing Gear & Parts Quote Today

For inquiries about trailer landing gear, trailer rims, or other trailer parts, contact us:

• Email: info.equilink@cimc.com

• Official website: http://www.cimc-equilink.com

Trust CIMC Equilink for high-quality, durable trailer parts—your partner for efficient logistics solutions.

Prev article: No Data Next article: CIMC Equilink: Trailer Landing GearQuick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文