-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistics Tools

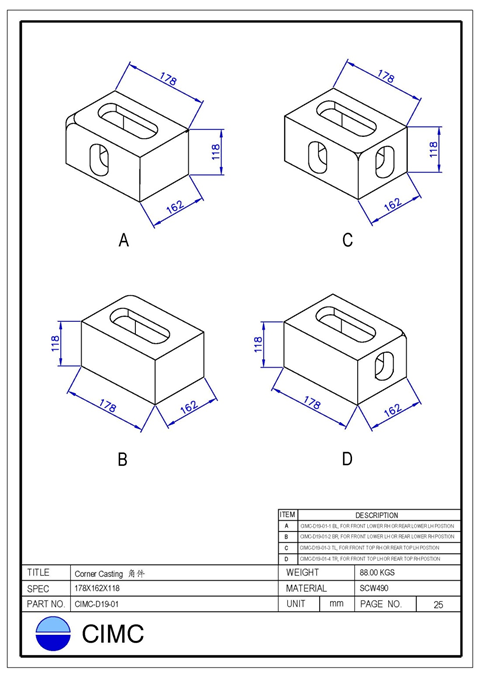

Container PartsScenario description of Container corner fittings and Lashing fittingsMar 07,2022Container corner castings are a small parts on the whole container but It is to say the container structure is supported by the container corner casting, and without the corner fitting the container is hard to work. All the works on containers are highly relied on the container corner castings including lift, movement, stacking, fix, etc. the corner fittings provide the necessary condition for container automation. The function of the container corner castings is to bear the complete weight of the container no matter it is empty or full loaded. All 8 pieces are evenly forced on the top and bottom.

The standard dimension of the container corner castings is 178 mm x 162 mm x 118 mm with 8 positions to be called as top left, top right, bottom left and bottom right.

There are also some special container corner fittings which are different with standard container corner castings. For containers are long than 40 feet, if the container corner castings are equipped as usual, then the dimension of the crane has to be changed. It will have additional cost and cause the low efficiency on operation and management for the port. The solution now is to add middle container corner castings. And the middle container corner castings are matched with the corner fitting on the rear end. So most cranes working on the ports can conform to the dimension for containers even longer than standard 40 feet.

Structure of Corner fittings

There is another type of container corner castings called EOC, European Overland Castings which is designed to conform with TCEU (Transport Council of Europe Union). That is to say the total length of the tractor along with the trailer should no longer than 16.5m according to EC96/53 regulation.

The container corner fittings from CIMC Intermodal Equilink are all used for container new building. Even though it is also a repair and maintenance container parts, CIMC container corner fittings are the same quality and production standard with new buildings. We can also offer container corner castings with or without the basic primer according to customer requirements.

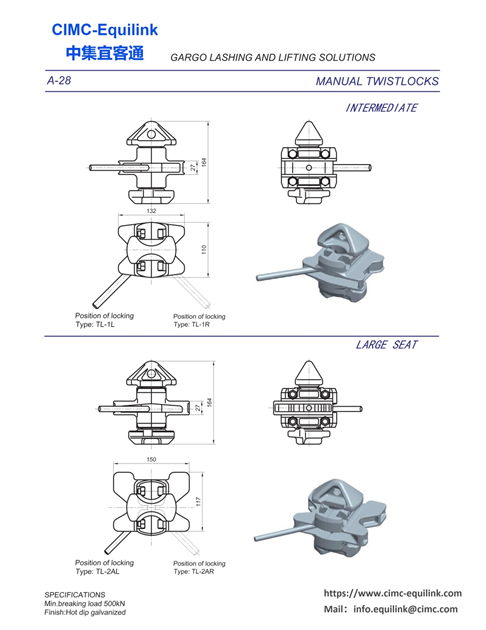

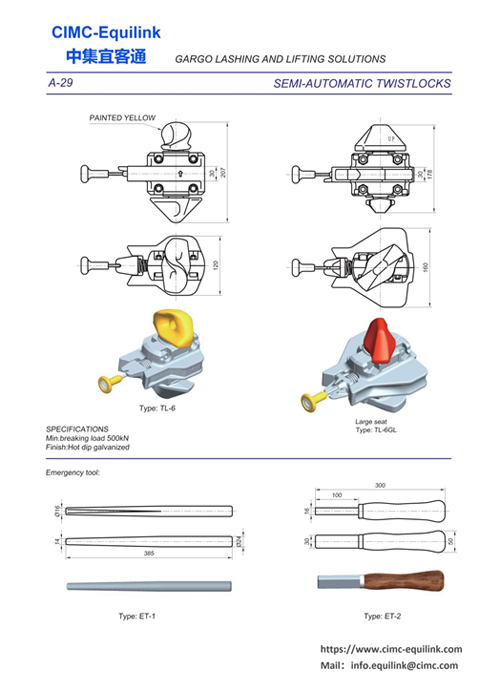

In addition to container corner castings, there is another parts very important which is container lashing equipment. During the shipment of the 20 feet container and 40 feet container, they must be secured on the vessel very firmly. So the container lashing equipment is very important. The container securing system is composed by many different container lashing equipment to solve the safety issue when the transportation on the sea. With the development for many years, it is getting very mature to have different container lashing equipment for different systems for both deck and cabin. The only difference for those container lashing equipment is for different purpose of the vessel such as container vessel, bulk vessel, roro vessel, etc.

Manual twistlocks

Semi-automatic twistlocks

The whole container securing system is to guarantee the safety and reliability during the transportation. The most common container lashing equipment we can see are twist lock, semi automatic twist lock, guide gone, raised foundation, lifting foundation, lashing rod, lashing plate.

CIMC Equilink provides a full range of containers, container parts and lashing equipments, which can be purchased with preferential prices, which is also the first choice of most of our existing customers.

New container and container parts shipped together

New container and container parts shipped togetherQuick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文