-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistics Tools

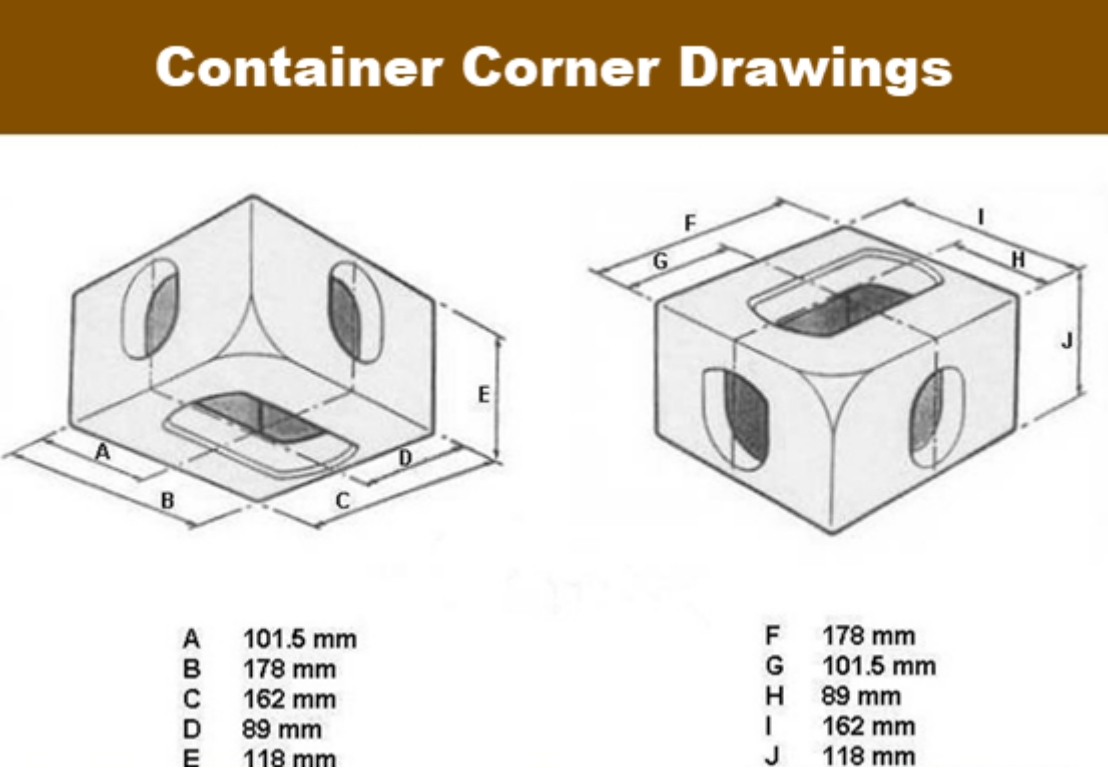

Container PartsCIMC Equilink | Container Corner CastingOct 09,2022Standard container corner castings, also known as container feet and hanging corners, should be familiar to this term, but do you know anything about the specifications of CORNER CASTINGS? The corner size of the national standard ISO1161 is 178x162x118mm, and the weight is about 11.2kg; the surface of the container corner pieces has no trachoma, no cracks, no holes in welding, and can also be used for lifting. The following drawing shows the size and length, width, and height of each hole in its corners.

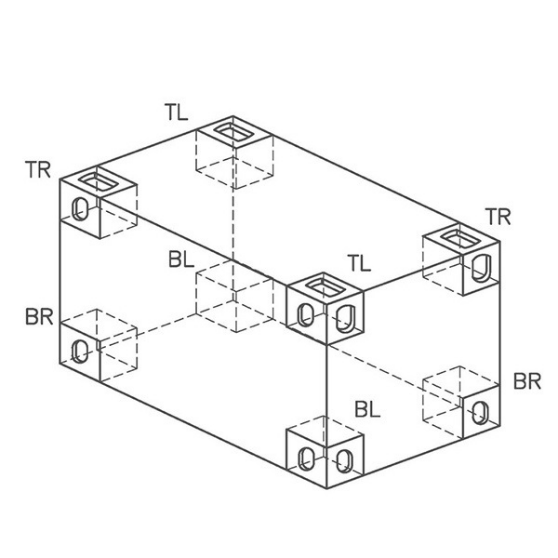

In addition to this 3D drawing, there are many knowledge points, such as its installation location. Container corner castings are divided into TR, TL, BR, BL. A container requires a total of eight corner castings, four at the top corner and four at the low corner; attach a three-dimensional space diagram and the actual container installation diagram for reference! When installing, the arc of the corner is on the outside, the holes on the three sides are also on the outside, and the surface without holes is connected to the container.

↑Installation drawing of each corner piece

Top hole:

It is a type of main hole, which is an opening on the top surface of the upper corner piece.

Bottom hole:

It is a type of main hole, which is an opening on the bottom surface of the upper corner piece.

End hole:

The opening on the end face along the length direction of the corner piece, the upper and lower corner pieces have end holes, but the shape of the hole is different.

Side hole:

The opening on the end face along the length direction of the corner piece, the upper and lower corner pieces have side holes, and the shape of the hole is the same.

Inner cavity:

When using attachments such as spreader turn locks, fishing hooks or shackles to carry or fasten containers, the turn locks or end bolts of these attachments must be inserted into the inner cavity of the container corner castings, so in addition to the required angle In addition to the sufficient strength of the parts, there must also be a certain inner cavity space, and there should be enough bearing surfaces, and the bearing area should not be less than 800mm2.

Why are corner castings installed on every container?

The role of container corner castings is to ensure the safe transportation of products without quality damage due to collisions. It plays an important role in the lifting, handling and fixing of containers. For the transmission of force, this requires that it must have good force bearing performance. When designing, it must be matched with the container to minimize the force.

↑Position diagram of corner castings in practical application

What to use to install container corner castings?

Most box factories or repair factories use carbon dioxide gas machines to weld the box corners, both sides are welded, the weld is 8mm, and it can only be welded once. Welding rod.

What are the mechanical performance requirements of container corner castings?

As the most important force-bearing component on the container, the corner piece of the container must withstand the changes from the equatorial heat to the polar cold zone, and it must withstand the static pressure of 7-layer stacking. Therefore, it needs to have high strength, toughness and plasticity, and must also have a certain low temperature impact toughness.

What are the strict inspection standards for container corner castings?

Standard: ISO 1161. Its inspection standard agencies include French BV, British LR, American ABS, German GL, and China CCS.

CIMC Equilink provides all kinds of dry container parts,. reefer container parts and iso tank parts. If you are looking for container parts or shipping containers for sale from china , or you just have questions about container declaration and transportation, please visit us by email(info.equilink@cimc.com)or submit a quick quote.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文