-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistic Tools

Container PartsSafety Guard - Twist LockNov 03,2022How the container stands firm in the wind and waves?

At the end of December 2020, a large container ship "E*** L***" encountered strong winds and waves in the sea area near Kyushu, Japan, on its way from Busan to Los Angeles. The severe weather caused thirty-six containers to fall into the sea and twenty-one 40'GP containers to collapse onto the deck.

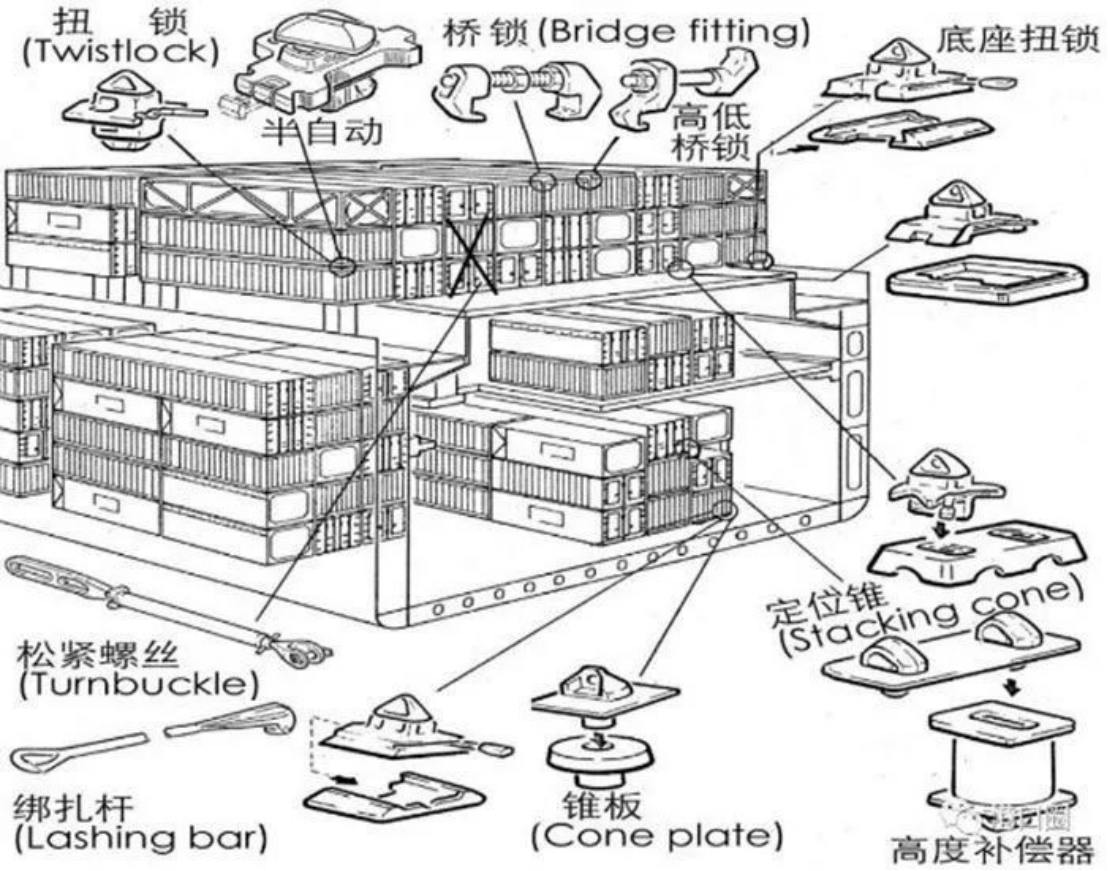

The containers on the ship would have displacement tendency due to factors such as ship movement and meteorological environment. Proper use of the container fastening equipment can effectively limit the movement of the container on the ship. The fastening equipment of container mainly include twist lock, bridge connection, pile cone, base, connecting plate and some tensioning devices.

Twist lock, also known as angle lock device, used for connection and fixation between upper and lower containers or containers and the hull. Twist lock is mainly used to lock the connection between two containers on deck to prevent overturning and sliding of containers.

Operating instructions: place the twist lock in corner casting hole of the lower base or the lower container and confirm that it is open. When the upper container is completely placed on the twist lock, pull the twist lock handle to lock it. When unloading, pull the wrench back to its original position and it will be in a loose state. After lifting the upper container, remove the twist lock to lift the lower container.

Twist locks are divided into three categories: manual twist locks, semi-automatic twist locks and automatic twist locks.

1. Manual twist lock:

The first deck container is usually fixed to the deck base with a manual twist lock.

2. Semi-automatic twist lock:

The spiral twist lock head produces a torque through the gravity release of the container box. And the lock head rotates to lock the box when it falls. When unloading, pull out the inhaul cable and it will be released. After lifting the upper container, remove the twist lock to lift the lower container.

3. Full-automatic twist lock:

The twist lock is forced into the corner casting hole of the lower container by the shape design of the lock tongue and the gravity effect of the container.

Under extreme sea conditions, the fully automatic twist locks may still be disengaged. Therefore, there are plans to use fully automatic twist locks together with semi-automatic and manual twist locks on the market, which improves the security of container fastening to a certain extent. However, there are also disadvantages of cumbersome operation as well as low loading and unloading efficiency. Personnel operation is dangerous as well.

The large deck can stack containers of six layers or higher. The weight on the four footing twist locks is a very huge number. If the ship encounters wind and waves or even turns at a large angle, it may cause the container to overturn. And overturned containers may damage goods and ship facilities, cause cargo damage and affect local strength of the ship. If it is serious, would affect the stability of the ship, causing it to capsize and sink. Therefore, the correct approach is to supervise in place on site during loading and unloading. In case of missing or wrong loading, notify the wharf in time, lift the shipping container with problems, and reinstall the twist lock to ensure sailing safety.

CIMC Equilink provides all types of container parts including twist locks, such as container corner casting , container floor , Container Locking Device , Lashing equipment , Container Corner Post , container Cross Member , container Gasket and even iso tank parts are our products that are very popular with customers.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文