-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

Container PartsHow to Repair a Damaged ContainerJul 09,2024Container damage is an unavoidable issue. Factors beyond our control can cause damage, so what should be done when it occurs? The extent of damage determines the action—repair the container promptly to avoid greater financial losses. However, the repair process can be lengthy and challenging, leading many to opt for insurance to mitigate disputes and high repair costs.

Reasons for Container Damage

Containers can sustain damage during loading, unloading, and transportation. Common causes include:

1.Excessive Pressure: Overloading can bend containers, especially when stacked.

Forklift Mishandling: Inexperienced drivers may cause containers to fall or stack unevenly.

2.Incorrect Container Use: Using the wrong container type for specific cargo can lead to damage.

3.Overloading/Uneven Loading: Can cause physical damage like cracks and holes.

4.Extreme Weather: Conditions such as heavy rain or condensation can cause corrosion and rust.

5.Contamination: Odors or pests from previous cargo can render containers unfit for the next shipment.

CIMC Equilink has been developing rapidly since its establishment. Empowered by abundant resources from CIMC Group, it is enabled to serve global clients with one-stop offer including rich products along with maintenance and repair technical support, to satisfy clients’ needs of services for small order quantity, high order frequency, full-range-category products and global reach delivery, which therefore makes clients' purchases more convenient and more costs saving. The products categories that we could supply include and not limited to containers and container modified products, logistics equipment, container and trailer spare parts, in addition to maintenance and repair tools.

Container Maintenance and Inspection Checklist

Maintaining containers is crucial for longevity and safety. Here’s what to include in your maintenance routine:

Inspection Content

Container Inspection Procedure Details

Prepare Documents

Record ISO inspection details—container number, inspector details, time, and date. Ensure the container is empty during inspection.

Visual inspection

Door

Inspect hinges, gaskets, seals, tie rods, retainers, cams, grooves, plates, corner posts, and fittings.

Walls

Check top and bottom rails, corner posts, forklift loading port, and sign brackets.

Front

Look at ISO number, sign brackets, corner posts/fittings, and panels.

Top

Verify ISO number, corner post fittings, top rails, door header top rails, top panels.

Bottom

Inspect corner post fittings, bottom rails, bottom side rails, door sills, beams, forklift access.

Interior Inspection:

Floor

Check floor, floor fasteners, door sills, fastening devices, and for light leakage.

Roof

Inspect top cross arch, top panel, and light leakage.

Sides

Verify plywood lining, kick rails, risers, rails, light leakage.

Front

Look at plywood lining, kick rails, risers, load-bearing surfaces, light leakage.

Summary:

Pass/Fail/Final Determination

Minor and major defects should be detailed by the inspector. Major defects require immediate repair. More than five minor defects indicate the need for repairs.

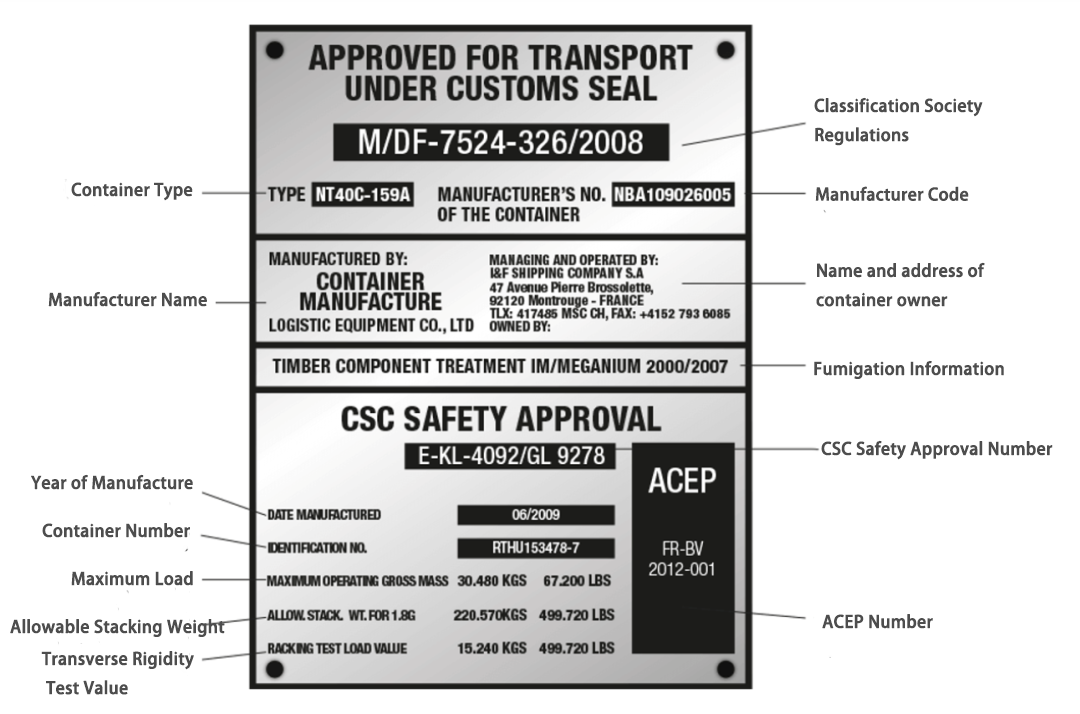

The Container Safety Convention (CSC) was created to develop standards for container repairs and to ensure personal safety during stacking and transport of containers. Once containers pass safety tests, they will receive a CSC safety plate. The following is the style of the CSC plate:

6 Common Container Damages and Repair Methods

Understanding how to manage and repair container damage is essential for minimizing costs and maintaining the integrity of your shipping operations.Rust Removal

Sandblasting is ideal for rust removal. Severe rust under the coating requires welding with a new steel plate.

Repairing the Container Floor

Plywood floors wear out over time. Replace floors with cracks to maintain integrity.

Replacing Door Seals

Essential for maintaining a waterproof and sealed container. Replace worn rubber seals promptly.

Repairing Paint

Regular touch-ups prevent paint wear and rust.

Repairing Holes and Cracks

Use UV industrial adhesive patches to fix holes and cracks caused by rust.

Reefer Container Repair

Pre-shipping inspection ensures all parts are in working order.

CIMC Equilink has been developing rapidly since its establishment. Empowered by abundant resources from CIMC Group, it is enabled to serve global clients with one-stop offer including rich products along with maintenance and repair technical support, to satisfy clients’ needs of services for small order quantity, high order frequency, full-range-category products and global reach delivery, which therefore makes clients' purchases more convenient and more costs saving. The products categories that we could supply include and not limited to containers and container modified products, logistics equipment, container and trailer spare parts, in addition to maintenance and repair tools.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文