-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

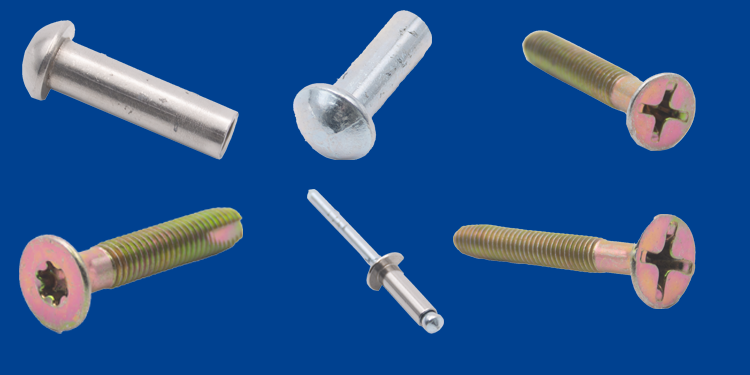

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

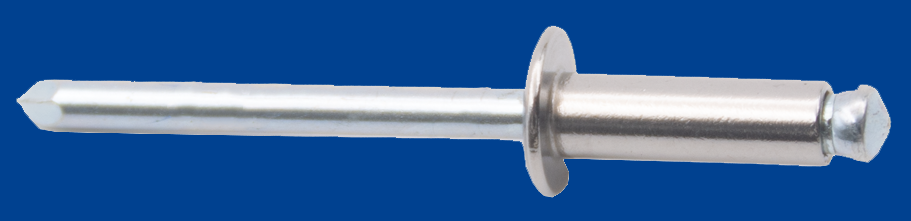

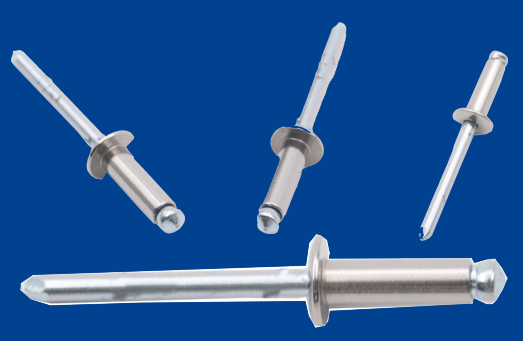

Container PartsThe Knowledge About Blind RivetsOct 29,2024Blind rivets are an essential mechanical fastening solution with unique characteristics and applications.

1. Composition and Manufacturing

A blind rivet is composed of two main parts: the rivet body, also known as the sleeve, and the setting device - the mandrel (sometimes referred to as the nail or rivet pin). The rivet body can be manufactured using three methods. The most common is from wire, which offers good overall performance and is widely used. Tubular rivet bodies, common in longer lengths, are not as strong as those drawn from wire. Sheet-made rivet bodies are the least popular and generally the weakest option.

2. How They Work

Blind rivets are designed to join workpieces together when access to the joint is available from only one side. They are inserted into a pre-drilled hole. The setting process involves pulling the mandrel head into the rivet body. This action expands the body, causing it to flare against the reverse side of the joint. As the mandrel head reaches the face of the blind side material, the pulling force is resisted. At a predetermined force, the mandrel snaps at its break point. What remains is a tight joint formed by the rivet body, with the head of the mandrel encapsulated at the blind side (although there are variations available). The mandrel stem is then ejected.

3. Factors to Consider in Selection

A. Rivet Joint Strength

The strength of the joint is a crucial factor. It depends on the materials used for the rivet and the workpieces, as well as the design and setting of the rivet. Different applications require different levels of joint strength, and the selection of the appropriate blind rivet must take this into account.

B. Joint Thickness

The thickness of the joint determines the length of the rivet needed. If the rivet is too short, it may not provide a sufficient grip and the joint may be weak. Conversely, a too-long rivet can cause difficulties during installation and may not form a proper seal or connection.

C. Nature of Rivet's Materials

The materials of the rivet itself play a significant role. Different materials have different properties such as strength, corrosion resistance, and compatibility with the workpieces. For example, in some applications where corrosion resistance is important, stainless steel blind rivets may be preferred over those made of other metals.

D. Hole Size

The size of the pre-drilled hole must be appropriate for the blind rivet. If the hole is too small, the rivet may not fit properly and installation will be difficult. If it is too large, the rivet may not provide a tight and secure joint, reducing the overall integrity of the connection.

E. Rivet Head Style

The style of the rivet head can affect the appearance and functionality of the joint. There are various head styles available, such as flat heads, round heads, and countersunk heads. The choice depends on the specific requirements of the application, such as the need for a flush surface or a particular aesthetic look.

When it comes to high-quality blind rivets, choose CIMC Equilink. Our rivets are crafted with precision using top materials and advanced techniques, meeting and exceeding industry standards for strength, durability, and reliability.

CIMC Equilink offers one-stop service with a full range of container accessories. Our blind rivets are the ideal fastening solution. With diverse sizes, materials, and head styles, you'll find the right fit. Trust us for top-notch rivets and rely on our comprehensive accessory range to meet all your needs. Please tell us your needs and questions by email(info.equilink@cimc.com) or submit a quick quote, we are very honored to serve you.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文