-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

Container PartsThe Functions and Processes of Container Roof PanelOct 29,2024In the vast world of logistics transportation, containers are like "steel giants," and the container roof panel are the "strong armors" on top of these giants. Today, let's dig deeper into the mysteries of container roof panel together!

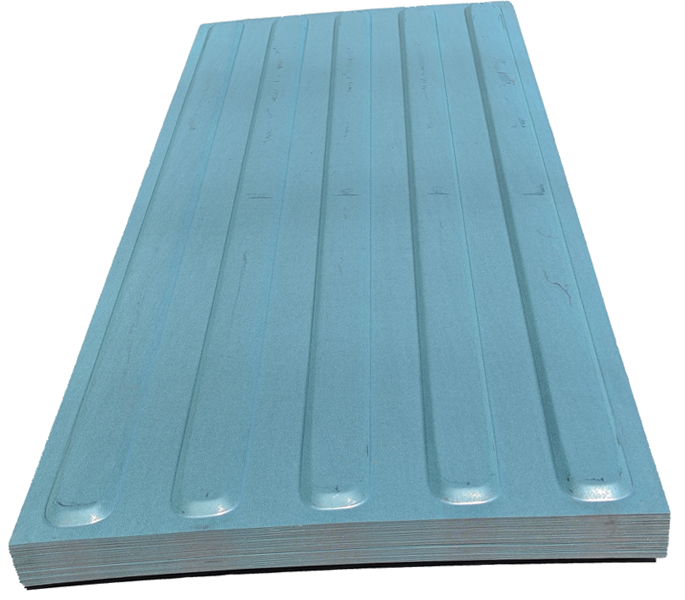

1. Overview of Container Roof Panel

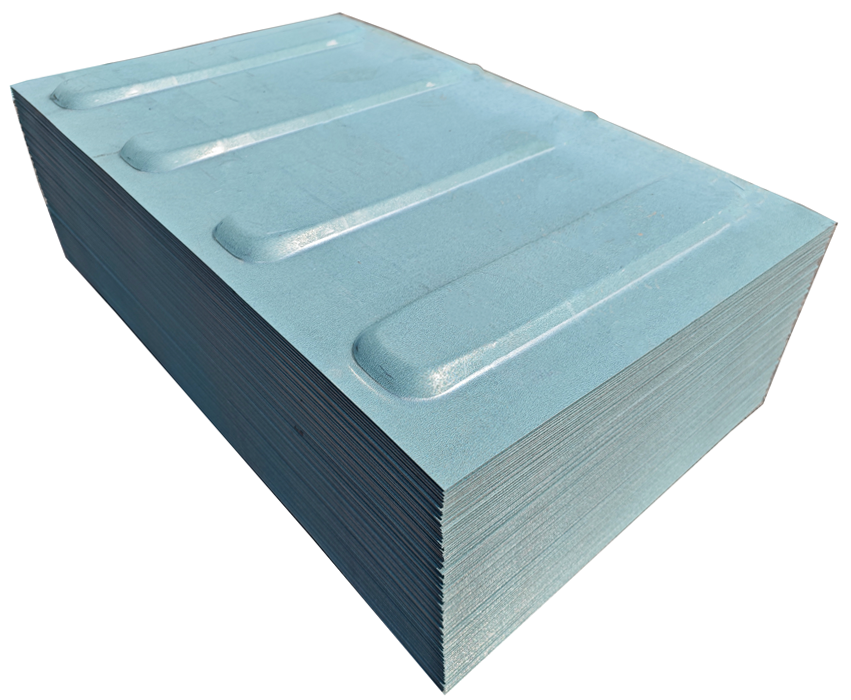

The container roof panel is located on the top of the container and is a key part of the entire box structure. It is made of steel material and acts like a strong guard, protecting the goods from wind and rain and safeguarding the internal safety. It has the characteristics of strong bearing capacity and good compression resistance, and can withstand various pressures from above. Whether it's multi-layer stacking or external impacts during transportation, it can remain as stable as a mountain. In logistics transportation, it not only prevents the goods from getting damp and damaged but also improves the efficiency of loading and unloading, making the logistics operations more smooth. It is an important barrier to ensure the safe and efficient transportation of goods.

2. Quality Standards of Container Roof Panel

2.1 Size Specifications

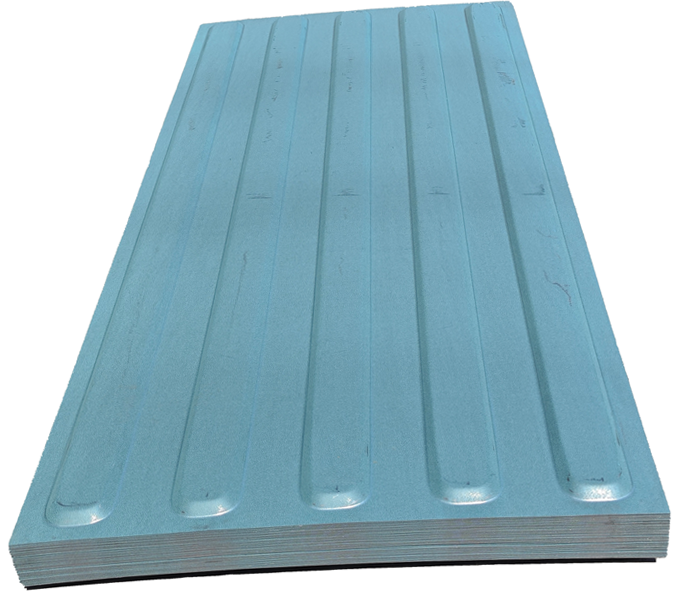

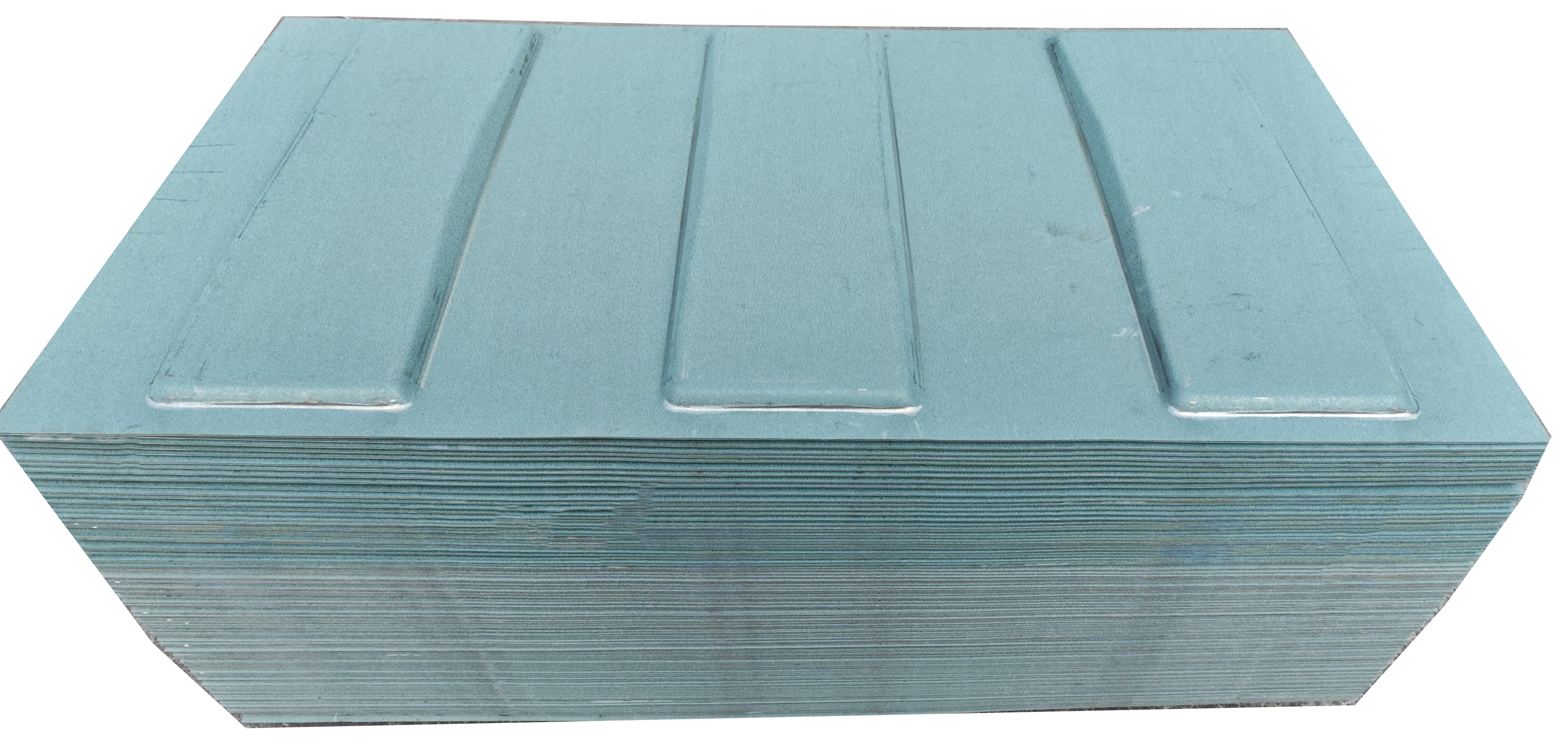

The size of the container roof panel has strict standards. The thickness is generally about 2.0mm, the width is commonly 1200mm, the length is about 2356mm, and the weight is around 44.38kg. The wave height is 25, the wave width is 91, the slope width is 13.5, the bending arc angle is R30, and the corrugation interval is 91. The standard roof panel is arranged with butt joints, while the customized one is arranged with lap joints, and the lap size is 25mm. These precise sizes ensure that the roof panel perfectly matches with other components, providing guarantee for the stability and safety of the container.

2.2 Material Types

The materials of container roof panel are diverse. Weathering steel has strong corrosion resistance and can adapt to harsh environments; galvanized sheet has good rust prevention performance and can extend the service life; cold plate has good surface quality and is suitable for occasions with requirements for appearance; hot plate has good strength and toughness and can withstand greater pressure. In corrosive environments such as ocean transportation, weathering steel and galvanized sheet are more applicable; in occasions with requirements for cost, cold plate and hot plate may be the preferred choices. Users can select the appropriate material according to actual needs.

3. Production Process of Container Roof Panel

3.1 Raw Material Preparation

High-strength steel, such as weathering steel, is usually selected for production. It contains specific proportions of elements and has characteristics such as strength, toughness, and ductility. It is suitable for manufacturing container roof panel and can withstand the pressures and impacts of complex transportation environments.

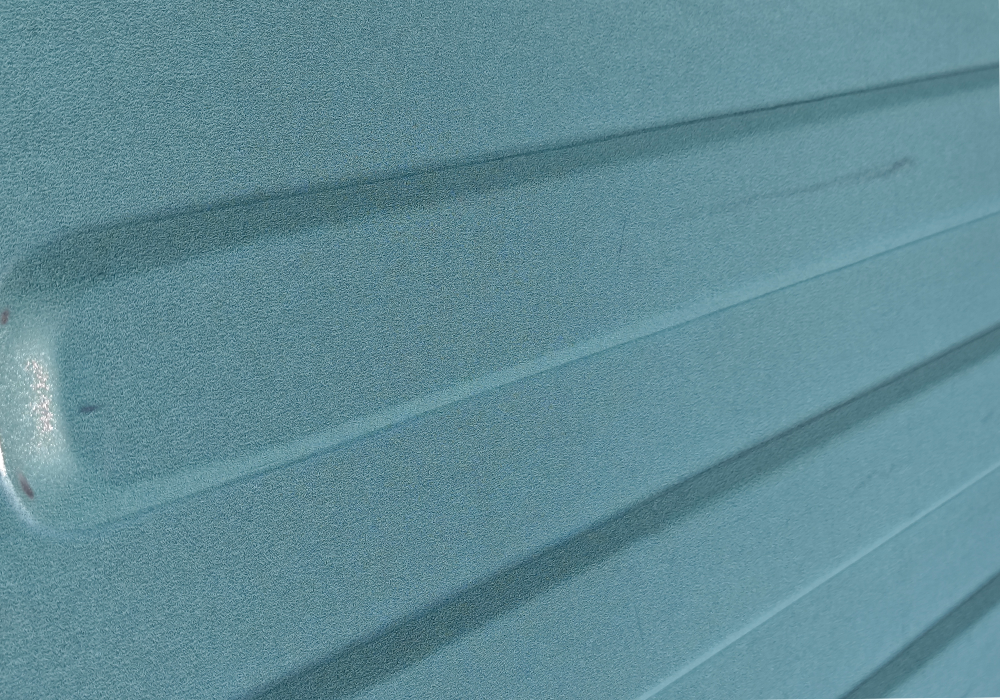

3.2 Steel Pretreatment

This is an important link. First, clean the impurities such as rust and oil on the steel surface, like "bathing" the steel, and then sandblast and spray primer to improve the surface quality and corrosion resistance. At the same time, preheat to improve the processing performance and reduce energy consumption. For example, the shot blasting cleanliness of the steel surface should reach the Swedish industrial standard SIS Sa2.5 level, and the roughness is 25 - 35μm.

3.3 Rolling Process

Put the pretreated steel into the rolling mill and extrude and stretch it into the required thickness and shape through the rollers. Controlling the roll pressure, speed, and temperature is crucial. The temperature of the billet at the roughing outlet should be ≥1100℃, and the finishing rolling temperature should be 860℃±20℃. Appropriate parameters ensure that the steel plate has uniform thickness and regular shape, laying a good foundation for forming.

3.4 Forming and Trimming

The pressing forming process is crucial. At least two bosses are formed at one time, which has obvious advantages. The size is stable, it saves materials and reduces costs, and also improves production efficiency. After forming, position and trim to make the size of the roof panel more accurate and better match with other components. Finally, perform treatment to remove burrs, edge coatings, and adjust the camber to make the roof panel beautiful and practical.

4. Functions of Container Roof Panel

4.1 Support and Anti-Slip

The roof panel plays an important supporting role on the top and bears the pressure from above. To prevent the container from sliding, anti-slip structures such as anti-slip strips are designed. For example, there are multiple strip-shaped raised limit strips and vertical anti-slip strips to increase friction and avoid sliding during transportation, improving safety. The anti-slip strips also make it safer for workers to walk on the top and reduce the probability of accidents.

4.2 Connection and Locking

The roof panel is equipped with locking and self-locking structures to ensure a firm connection with the upper container. For example, some devices, the end door switch drives the locking part to achieve locking and unlocking, and there are locking structures installed inside to connect and lock the upper container, and the self-locking structure drives the locking and unlocking. These structures ensure that the upper and lower containers are closely connected during transportation and will not be separated due to bumps and shakes, ensuring the safe transportation of goods.

5. The Container Roof Panel of CIMC Equilink

The container roof panel of CIMC Equilink have many advantages. Their quality is reliable and guaranteed. They are strictly inspected in the whole process service, and high-quality materials are selected. CIMC Equilink provides one-stop supply services and can offer a full range of container products. Using the container roof panel of CIMC Equilink can make your container have higher efficiency and safety.

Please tell us your needs and questions by email(info.equilink@cimc.com) or submit a quick quote, we are very honored to serve you.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文