-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

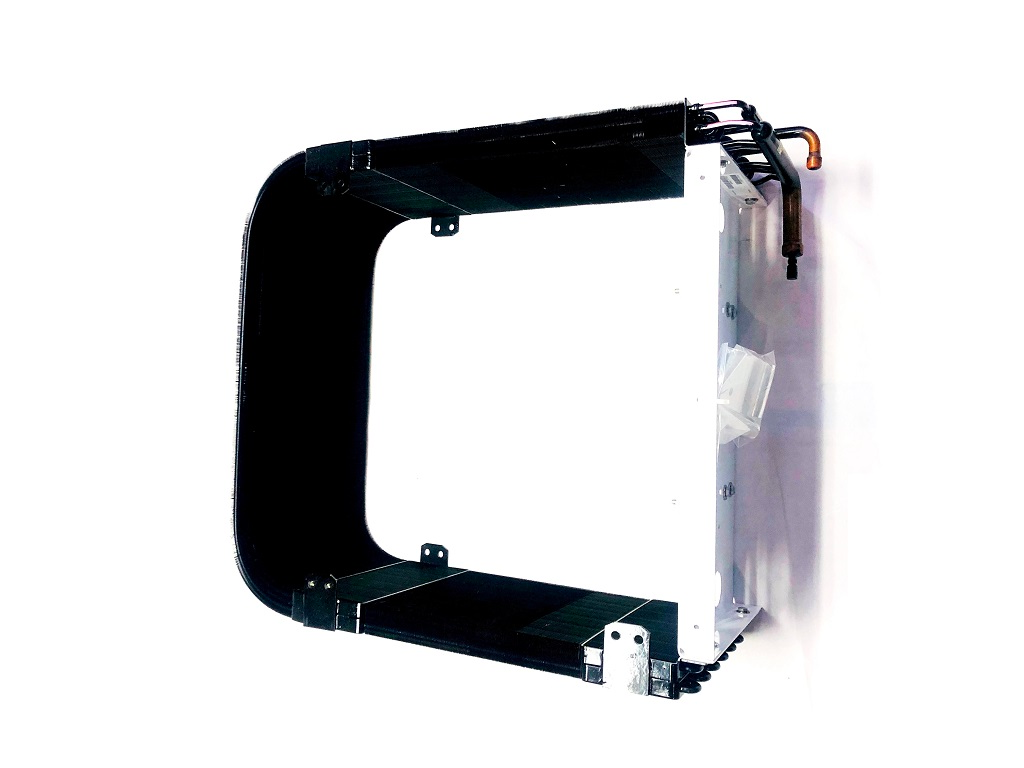

Container PartsReefer Unit Parts (2) - Condenser CoilMar 28,2025In refrigerated shipping containers, the reefer condenser coil is a critical component responsible for efficient heat dissipation, ensuring cargo integrity in extreme temperatures. Two key variants dominate the market, each tailored to specific operational demands.

C-Type Condenser Coil Specifications

- Material: Copper construction offers superior thermal conductivity and corrosion resistance.

- Fin Spacing: 18 fins per inch maximize surface area for rapid heat exchange.

- Rows: Two rows balance compact design with high-performance cooling.

- Pressure Rating: Withstands up to 300 PSIG, ideal for high-pressure refrigerant systems.

- Coating: E-coat finish enhances durability in harsh maritime environments.

Standard Condenser Coil Specifications

- Material: Copper-aluminum hybrid for cost-effective thermal management.

- Fin Spacing: 13 fins per inch reduce airflow resistance in dusty or dirty conditions.

- Tubing: 3/8" tubing optimizes refrigerant flow for consistent cooling.

- Rows: Four rows increase capacity for larger reefer units.

Why Condenser Coil Design Matters

A high-quality reefer condenser coil directly impacts energy efficiency, maintenance costs, and system lifespan. Copper variants excel in corrosive saltwater environments, while hybrid designs offer a balance between performance and affordability. Fin spacing and row count influence airflow dynamics—denser fins boost heat transfer but require more frequent cleaning, whereas wider fins reduce blockages in dirty settings.

Selecting the Right Condenser Coil for Your Reefer

Operators should prioritize compatibility with refrigerant type, environmental exposure, and space constraints. For coastal or humid routes, C-type coils with E-coat protection are ideal. In dusty inland logistics, standard coils with wider fins minimize downtime. Always verify pressure ratings and material compliance with ISO 14526 for marine refrigeration systems.

Elevate Reefer Efficiency with CIMC Equilink

For reliable, high-performance reefer condenser coils, explore CIMC Equilink’s precision-engineered solutions. Their coils are designed to meet rigorous industry standards, ensuring optimal heat dissipation, corrosion resistance, and longevity. Whether for new builds or retrofitting, CIMC Equilink’s condensers deliver unmatched performance in even the most challenging reefer applications.

Investing in a durable, efficient reefer condenser coil is key to minimizing operational risks and maximizing cargo protection. Stay ahead in refrigerated logistics by choosing the right technology for your fleet.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文