-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

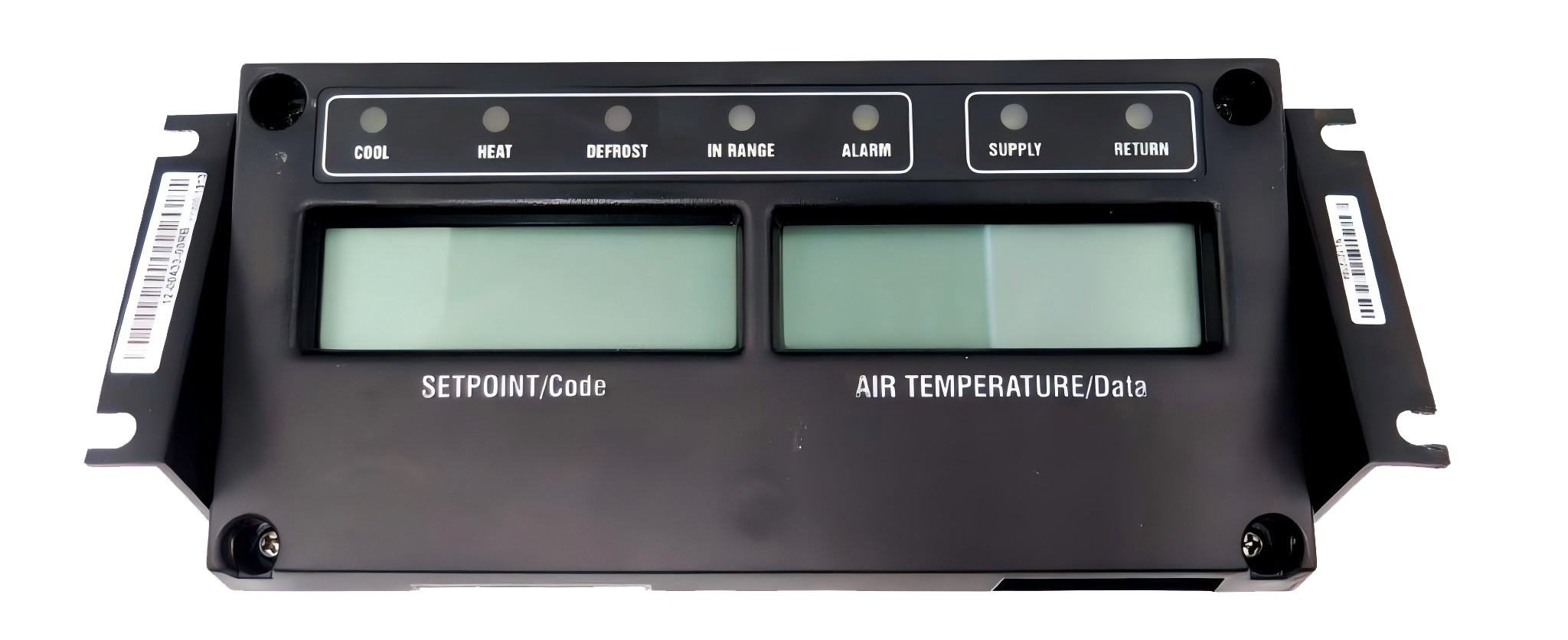

Container PartsReefer Unit Parts (3) - Display ModulesApr 01,2025In refrigerated shipping containers, real-time monitoring of temperature, humidity, and system status is non-negotiable for cargo integrity. At the heart of this functionality lies the reefer units - display module, a sophisticated interface designed to deliver precise, actionable data. Here’s what operators need to know about selecting and maintaining these vital components.

Key Specifications for Reefer Display Modules

- Display Type: LCD technology ensures clear visibility even in low-light or extreme temperature conditions.

- Board Material: Glass epoxy laminates (NEMA G10 or FR4) provide superior mechanical strength and flame resistance, critical for reefer environments.

- Temperature Range: Operational durability spans -40°C to 85°C, while non-operational resilience extends to -45.5°C, making them suitable for global logistics.

- Application: Primarily used for visual readouts, these modules support diagnostics, alarms, and user-friendly control interfaces.

A faulty reefer units - display module can lead to misinterpreted data, delayed maintenance, or even cargo spoilage. High-quality modules meet rigorous standards, such as MIL-STD-202 for shock and vibration resistance, ensuring reliability across rough sea or land transport. Their robust construction also minimizes downtime, reducing costly repairs in the field.

Choosing the Right Display Module for Your Reefer

When selecting a reefer units - display module, prioritize compatibility with your reefer’s control system and environmental exposure. For Arctic or tropical routes, opt for modules certified to withstand extreme temperatures. Look for IP65 or higher ratings for dust and water resistance, especially in coastal or high-humidity regions. Additionally, ensure compliance with ISO 14526 for marine refrigeration systems.

Enhance Reefer Efficiency with CIMC Equilink

For cutting-edge reefer units - display modules, CIMC Equilink offers advanced solutions engineered to meet the toughest industry demands. Their modules feature sunlight-readable LCDs, rugged G10/FR4 boards, and extended temperature ranges, ensuring seamless operation in every climate. With intuitive interfaces and fail-safe diagnostics, CIMC Equilink’s display modules empower operators to maintain optimal reefer performance while reducing operational risks.

Investing in a reliable display module is an investment in cargo safety and operational efficiency. Stay ahead in refrigerated logistics by choosing a module that combines durability, accuracy, and ease of use.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文