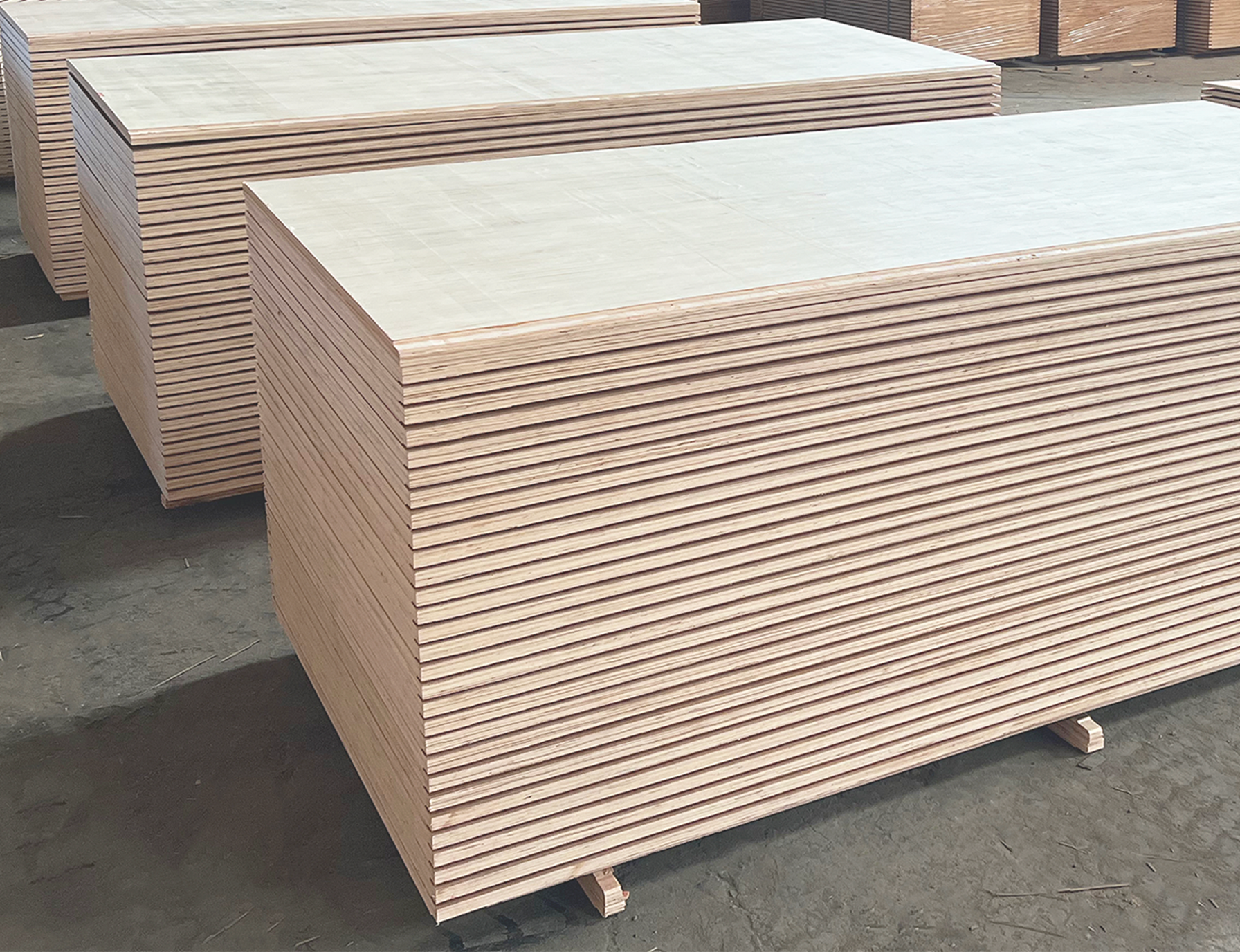

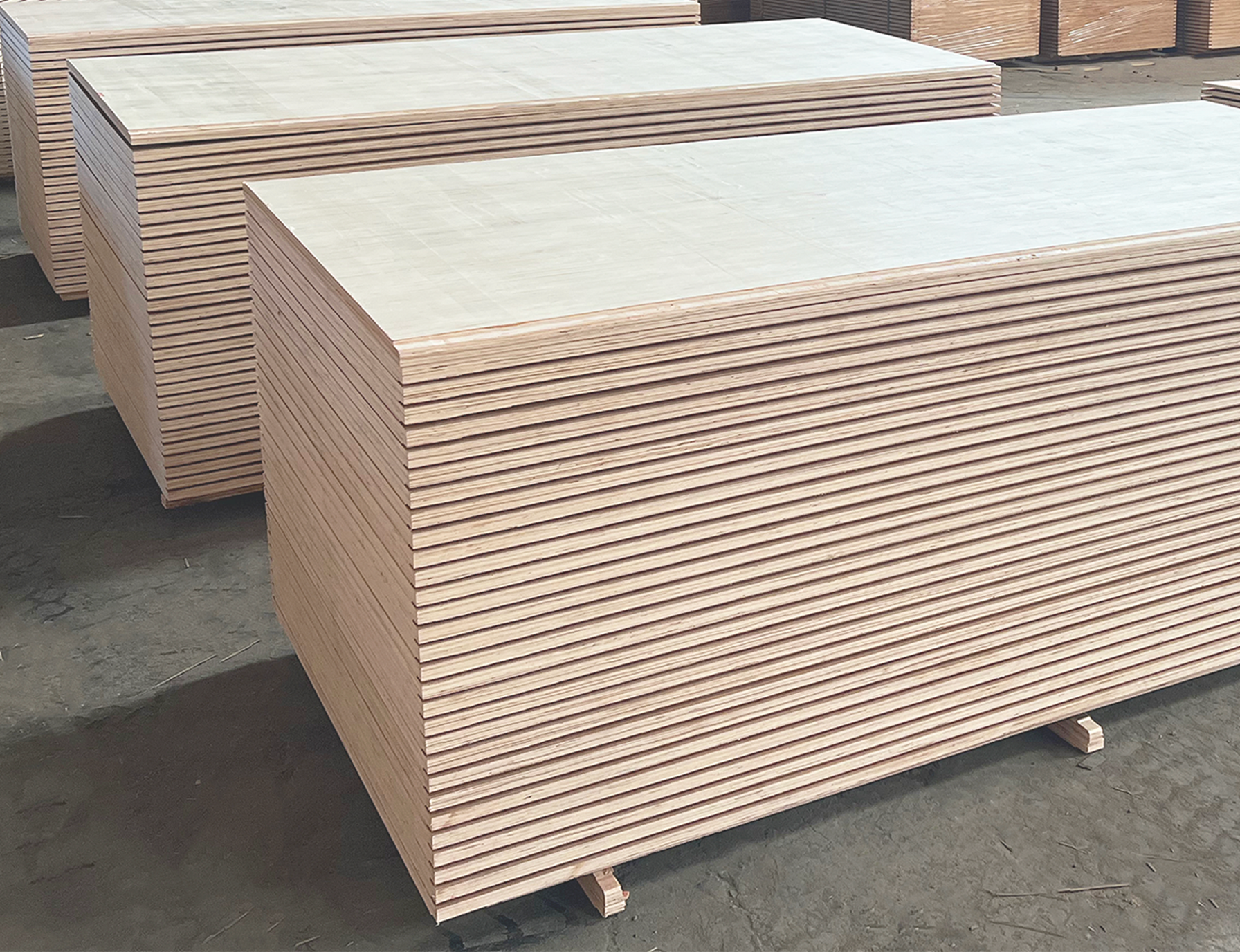

The production process of

container plywood flooring is complex and rigorous. The first is the raw material procurement link, carefully selecting high-quality wood or bamboo and other raw materials, such as suitable tropical wood such as Keruing, Apitong, etc. These woods must have good physical properties and meet the strength and weather resistance requirements of container plywood flooring.

In the raw material processing stage, the wood is cut and dried to control the moisture content of the wood within a suitable range, generally required to be ≤12%, to prevent the floor from deforming due to moisture content problems in subsequent use. Then enter the gluing process, use high-performance waterproof resin glue to glue the treated wood veneer or bamboo unit. During the gluing process, add approved special insect repellents and preservatives, such as products approved by Australia's AQIS, to ensure that the floor has insect repellent and anti-corrosion properties.

Then comes the hot pressing molding link, where pressure is applied by a professional high-tonnage press to tightly combine the glued materials. Due to its strong toughness, bamboo usually requires more than twice the pressure of ordinary wood. The formed floor needs to be processed later, such as trimming and sanding, to make it accurate in size and smooth on the surface. Finally, the finished product is strictly inspected for quality, including appearance, size, physical properties, etc. Only products that pass all the inspections will enter the market. Every production link is strictly controlled to ensure the high-quality output of

container plywood flooring.

CIMC Equilink

CIMC Equilink has advanced production equipment and mature production processes. From the source to the finished product, it strictly controls the entire process to create high-quality container plywood flooring for you.

中文

中文