There are many testing methods for

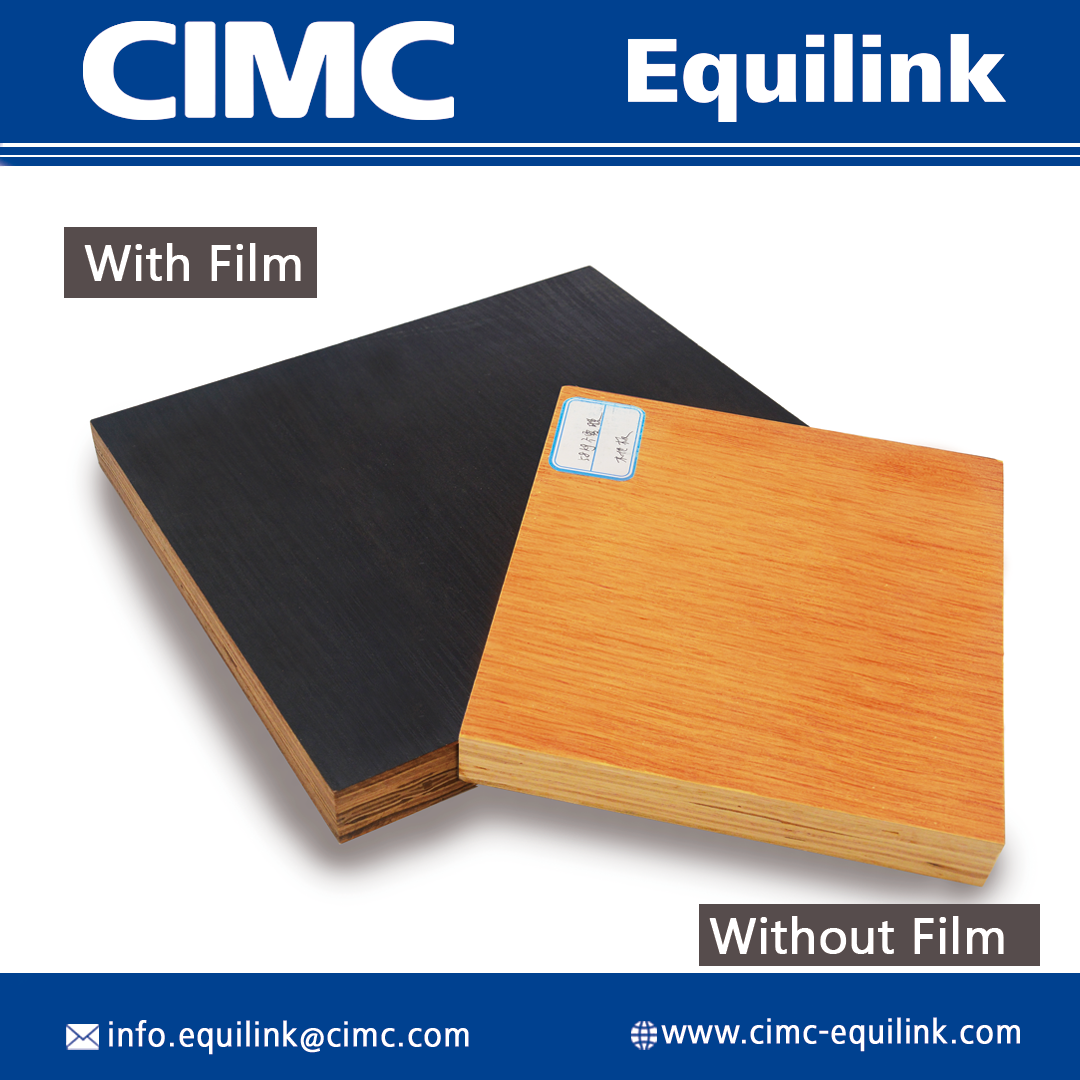

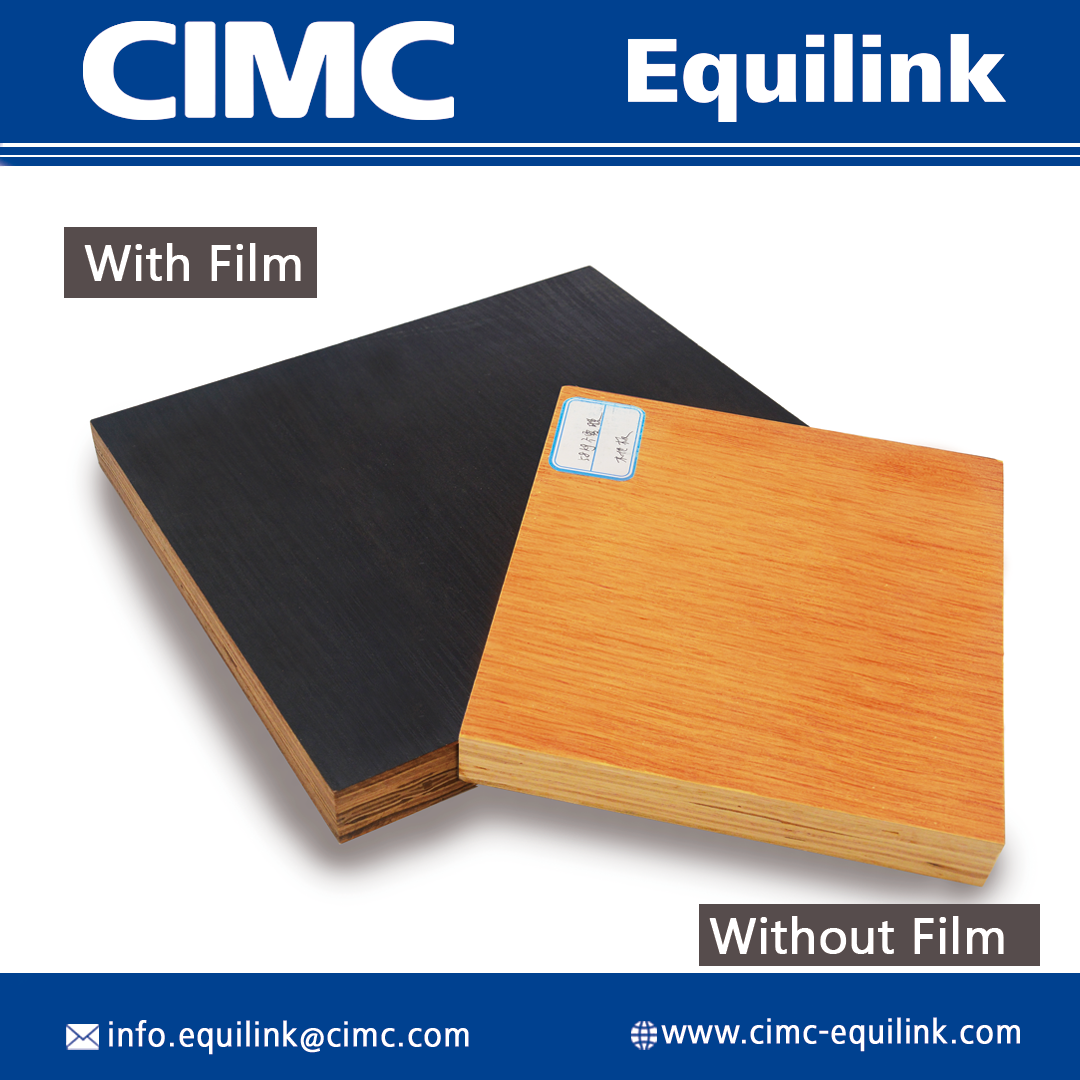

container plywood flooring to ensure that its quality meets the standards. Appearance inspection is the basis. Through naked eye observation and touch, check whether the floor surface is flat and smooth, whether there are defects such as cracks, missing corners, delamination, and whether the color is uniform.

Dimension inspection uses professional measuring tools to accurately measure the length, width, and thickness of the floor. Compare with the standard specifications to determine whether its dimensional tolerance is within the allowable range. For example, the length and width tolerance and thickness tolerance of common specifications have clear standards. In terms of physical performance testing, static bending strength testing simulates the situation where the floor is under pressure and tests its bending degree under a certain pressure. The static bending strength is required to be ≥85MPA; elastic modulus testing is used to evaluate the ability of the floor to resist deformation when subjected to force, generally requiring ≥10000MPA; bonding strength testing is to test the bonding strength between the layers of floor materials, and the bonding strength must be ≥1.7PA. In addition, a cyclic cooking test is also conducted to simulate the performance changes of the floor in a humid environment; the bending test examines the performance of the floor when it is bent and stressed; the shear test evaluates the floor's ability to resist shear force; the box pressing test simulates the load-bearing capacity of the floor under the actual packaging state, etc. A variety of testing methods are used in combination to fully guarantee the quality and reliability of container plywood flooring.

CIMC Equilink

CIMC Equilink uses professional testing methods to strictly test each piece of container plywood flooring to ensure the high quality of the product, so that you can use it without worry.

中文

中文