-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

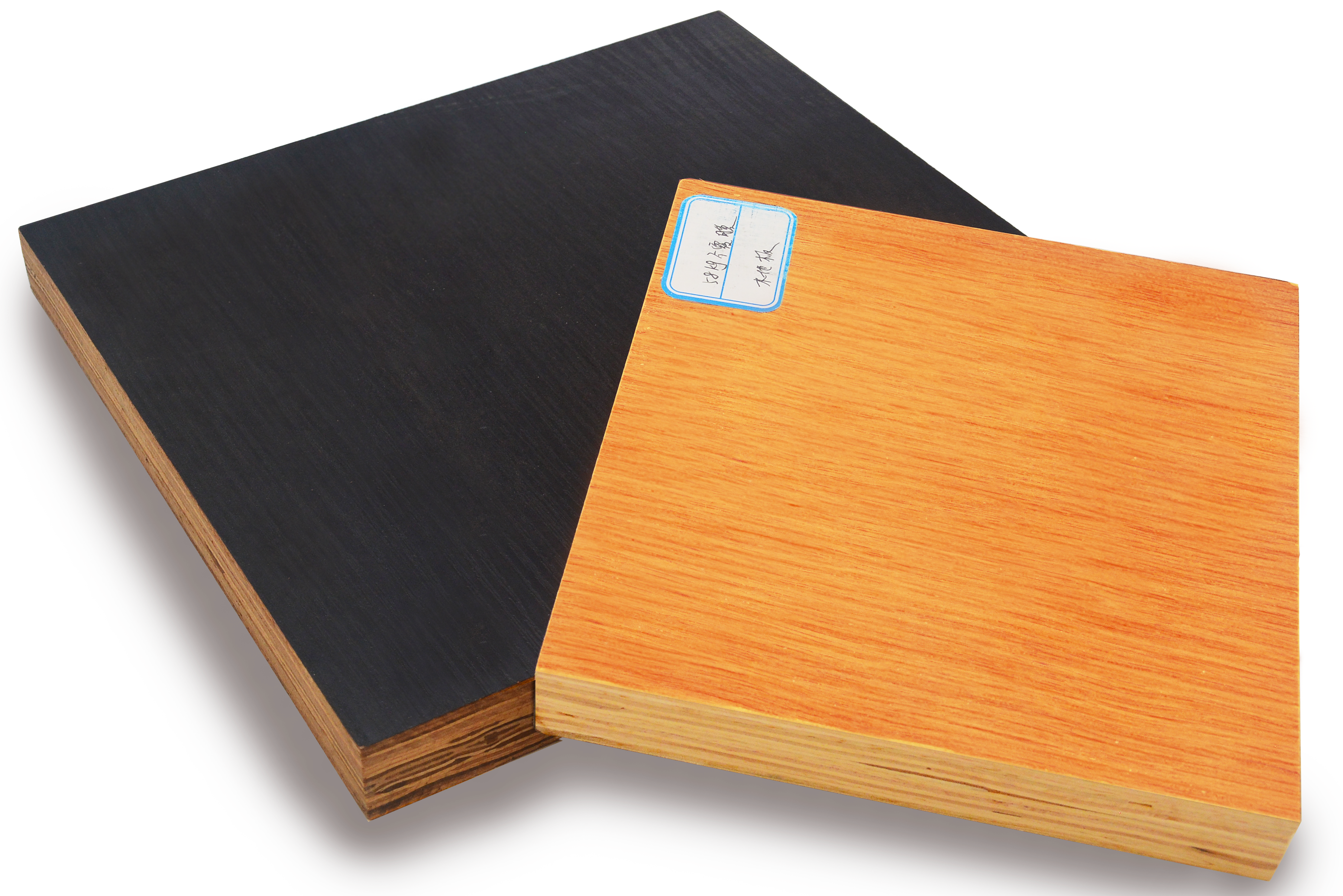

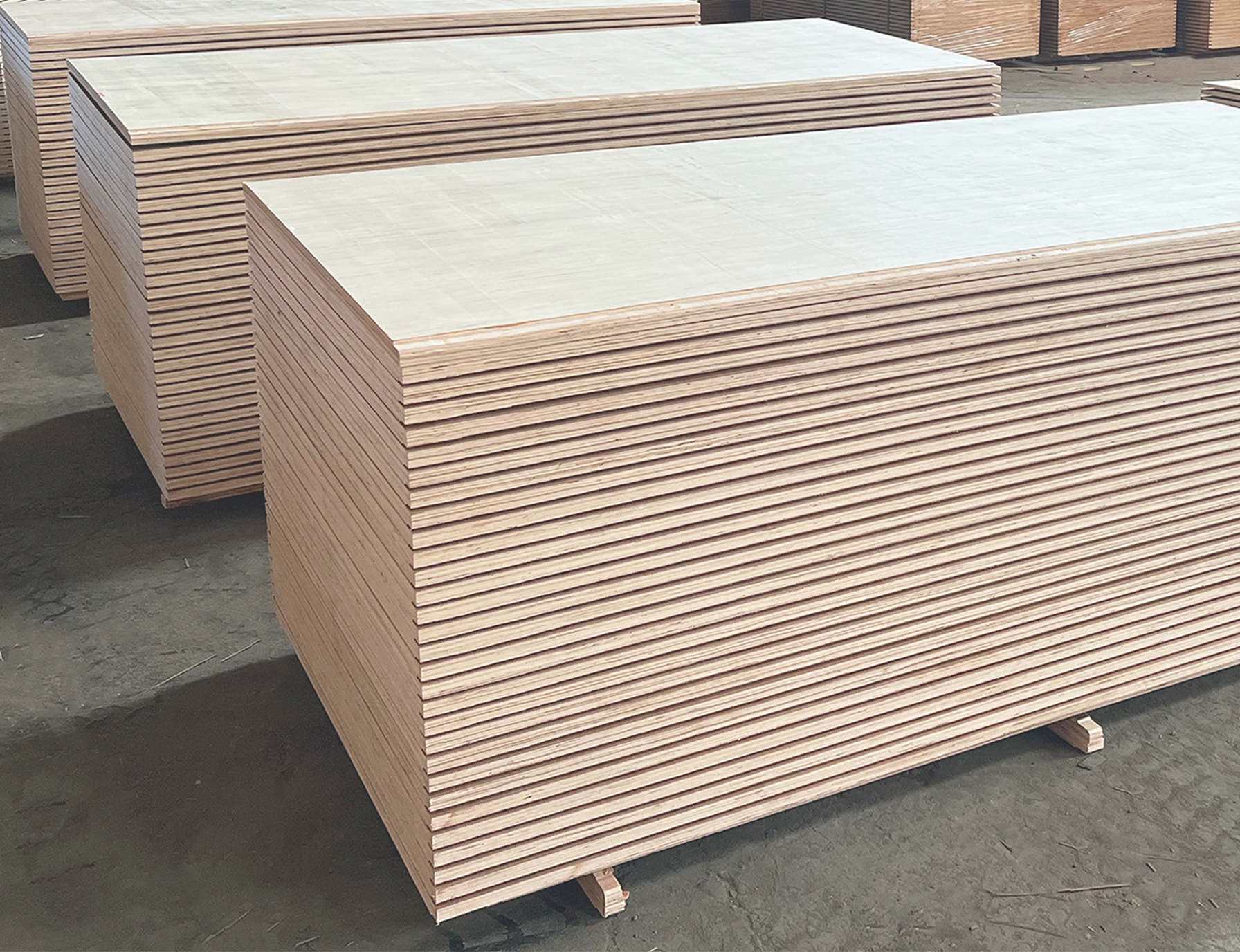

Container PartsTesting Process of Container Plywood FlooringJul 04,2025The testing process of container plywood flooring covers multiple key steps and professional technologies. In the sampling stage, we follow the principle of scientific sampling and extract representative samples from the mass-produced container plywood flooring to ensure that the test results can reflect the quality of the entire batch of products.

During the appearance inspection, the inspectors carefully check the surface of the floor with rich experience and professional vision, and do not miss any minor defects to ensure that the surface of the floor is flat, free of cracks, missing corners, delamination, etc., and the color is uniform. Dimension inspection uses high-precision measuring instruments such as calipers and micrometers to accurately measure the length, width, and thickness of the floor, strictly compare the standard size tolerance, and the tolerance range of common specifications is clearly defined.

The physical performance testing process is more complicated. The static bending strength test requires placing the sample on a professional testing device, applying pressure according to the standard loading procedure, and measuring the bending deformation of the floor under a specific pressure. The static bending strength is required to reach ≥85MPA. The elastic modulus test measures the deformation of the floor during the force process and calculates its ability to resist deformation. The standard value is generally ≥10000MPA. The bonding strength test uses a special bonding strength test equipment to conduct a specific way of destructive testing on the floor samples to test the bonding strength between the layers of materials, which must be ≥1.7PA. In addition, the circulating cooking, bending, shearing, and box pressing tests have their own corresponding professional testing equipment and standardized operating procedures. By simulating various actual usage scenarios, the quality and performance of container wood floors are comprehensively evaluated. Rigorous testing technology is the key line of defense to ensure the quality of container wood floors.

CIMC Equilink uses advanced testing technology, equipped with professional testing equipment and personnel, to conduct all-round and strict testing of container wood floors to provide you with excellent quality products.

Prev article: No Data Next article: Testing Methods for Container Plywood FlooringQuick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文