-

Shipping Containers

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 79. Electrical Equipment

- 81. Packing & Jointing

- Vehicles

- Lashing Tools

- Logistic Tools

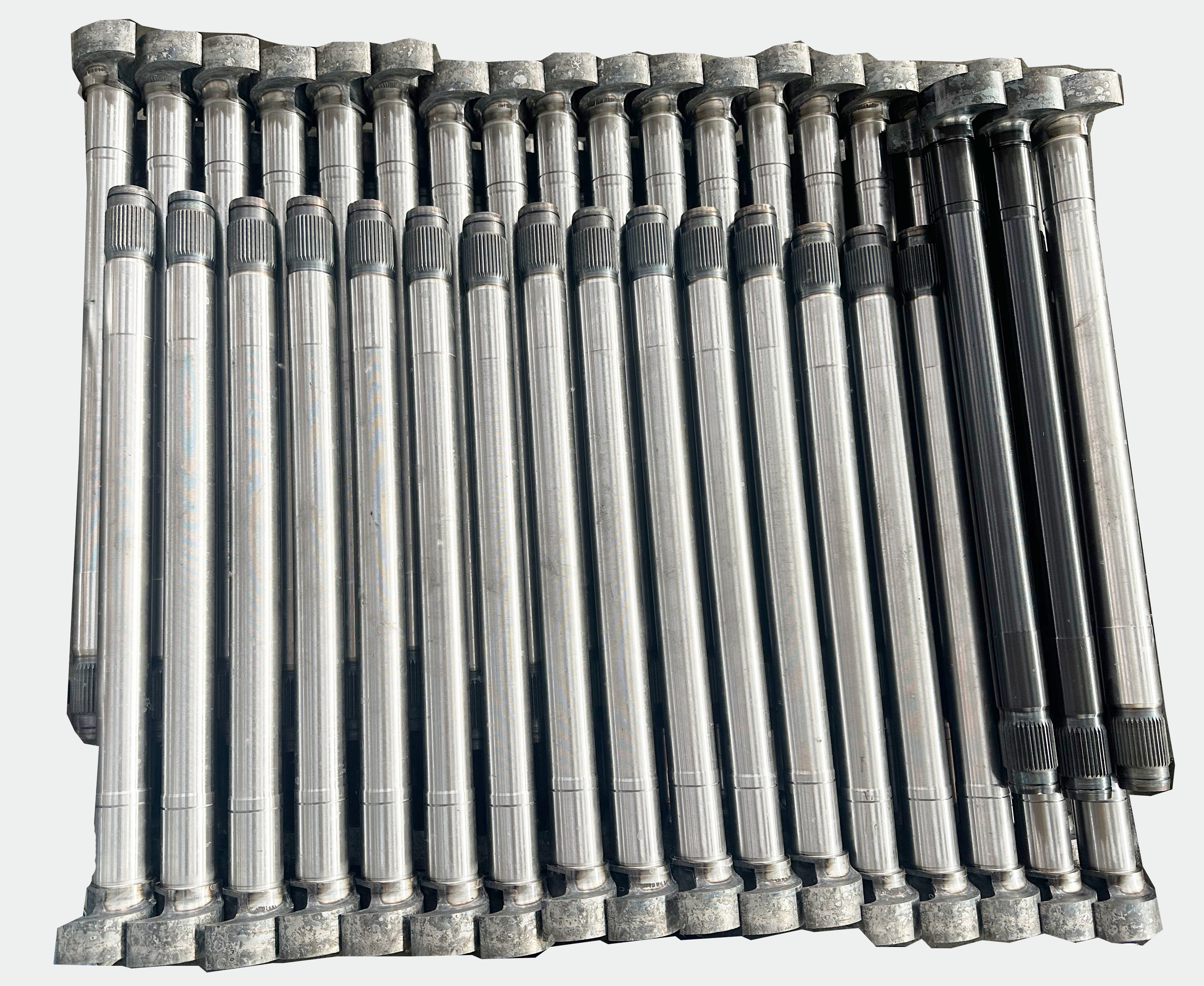

Vehicle PartsCIMC Equilink Camshaft Product IntroductionOct 18,2024Among the core components of an engine, the camshaft plays a crucial role. CIMC Equilink's camshaft products stand out in the market with their excellent design and manufacturing processes. The following will combine the general characteristics of camshafts to detail the unique features of CIMC Equilink camshafts.

1.Structural Design

1.1 Fusion and Innovation of Characteristics of Underhead Camshaft

Some of CIMC Equilink's camshaft products adopt some classic design elements of underhead camshafts. For example, in terms of the connection with the crankshaft, various reliable connection methods are also considered. Just like the common ways of connecting with the crankshaft using star gear sets (control wheels), roller chains or racks, ensuring the stability of power transmission. At the same time, in material selection, in order to control noise, it also follows the excellent tradition of underhead camshafts. The transmission wheels at the end of the relatively large-diameter camshaft are made of suitable plastics or light metals, while the transmission wheels at the end of the relatively small-diameter crankshaft are made of steel. This material combination effectively reduces noise during transmission and improves the usability comfort of the product.

1.2 Optimization of Overhead Camshaft Structure

In terms of the overhead camshaft structure, CIMC Equilink also has outstanding performance. Its products adopt a similar connection method as the common plastic rack chain connection and optimize this structure. The rack chain is located outside the engine oil chamber and is attached with steel embedded components and is tensioned by an adjustable roller. This design not only ensures the effective connection between the camshaft and other components but also improves the stability and reliability of the entire structure, reducing the risk of failure caused by connection problems. At the same time, for some relatively complex but previously used structures, such as connecting the overhead camshaft and the crankshaft through eccentric connecting rods, star gear sets or bevel gear sets with intermediate shafts, CIMC Equilink, after in-depth research and technical improvement, may adopt an optimized similar structure in some special application scenarios to meet specific power transmission needs while avoiding the problems of excessive power loss and excessive complexity of the original structure.

2. Transmission Methods

2.1 Comprehensive Application of Multiple Transmission Methods

In terms of the transmission method between the CIMC Equilink camshaft and the crankshaft, the advantages and disadvantages of different transmission methods are fully considered. For the transmission between the lower-mounted camshaft and the mid-mounted camshaft and the crankshaft, cylindrical timing gear transmission is mostly used, which is a reliable transmission method proven by practice. Generally, only one pair of gears is needed for transmission from the crankshaft to the camshaft. If the transmission gear diameter is too large, an additional intermediate idler gear can be added. In order to ensure smooth meshing and reduce operating noise, timing gears mostly use helical gears. This design ensures efficient and stable power transmission.

2.2 Reasonable Selection of Chain Transmission and Toothed Belt Transmission

For the transmission between the overhead camshaft and the crankshaft, CIMC Equilink makes a reasonable selection according to different engine requirements. Chain transmission is still used in some products. Although its working reliability and durability are not as good as gear transmission, in some specific application scenarios, chain transmission has its unique advantages. At the same time, with the development of technology in recent years, on some high-speed engines, CIMC Equilink also widely uses toothed belts instead of transmission chains. Toothed belts have the characteristics of low operating noise, reliable operation, and low cost, meeting the comprehensive requirements of modern engines for performance and cost. For double overhead camshafts, in CIMC Equilink products, generally, the exhaust camshaft is driven by the crankshaft through a timing toothed belt or chain, and the intake camshaft is driven by the exhaust camshaft through a metal chain, or both the intake camshaft and the exhaust camshaft are driven by the crankshaft through a toothed belt or chain. This reasonable selection of driving methods ensures the smooth intake and exhaust of the engine and improves the overall performance of the engine.

3. Installation and Maintenance

3.1 Pay Attention to Timing Marks

When installing a CIMC Equilink camshaft, just like other camshaft products, be sure to pay attention to the timing marks on the camshaft pulley or sprocket. This is a key link to ensure the normal operation of the engine. Some engines do not have obvious timing marks. In the product design and accompanying instructions of CIMC Equilink, maintenance personnel will be guided to mark the accurate positions of the crankshaft and camshaft before disassembling the camshaft to facilitate subsequent installation and maintenance. For some engines that require special tools for timing adjustment, CIMC Equilink will also provide corresponding technical support and tool suggestions to ensure that users can correctly install and maintain camshaft products.

3.2 High-Quality Assurance and Convenient Maintenance

CIMC Equilink camshaft products, with their high-quality manufacturing processes and material selection, not only have stable performance during normal use but also have certain convenience in maintenance. The product structure is reasonably designed, and the connections between various components are tight and easy to inspect and maintain. At the same time, the company also provides perfect after-sales service to provide timely solutions to problems encountered by users during use, ensuring that users can use CIMC Equilink camshaft products stably for a long time.

CIMC Equilink's camshaft products show excellent performance and quality in structural design, transmission methods, installation and maintenance. By fusing and optimizing the design characteristics of various camshafts and combining advanced manufacturing processes and technologies, it provides stable and reliable power transmission for engines and meets the needs of different users and engine application scenarios.

Over the years, it has established long-term business relationships with many clients and suppliers and gained a high industry reputation. Please tell us your needs and questions by email(info.equilink@cimc.com) or submit a quick quote, we are very honored to serve you.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文