-

Shipping Containers

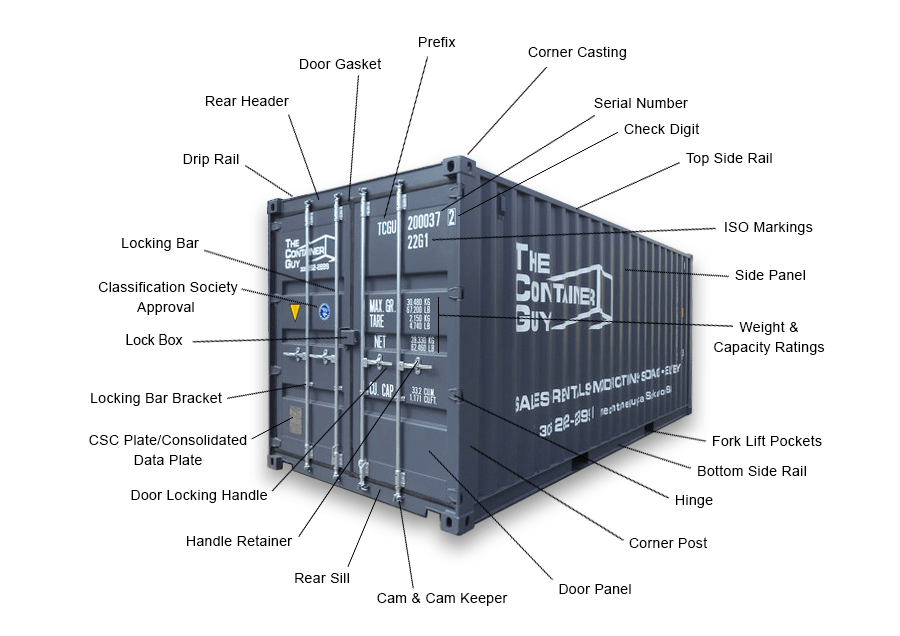

- Container Parts

- Roof Panel

- Side Panel

- Front End Panel

- Door Panel

- Front Corner Post

- Rear Corner Post (Outer/Inner)

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Door Sill

- Front Bottom Rail

- Top End Rail

- Door Header Upper/Lower

- Door Rail

- Floor Spacer

- Angle

- Top/Bottom End Rail

- Door Edge Member

- Door Sealing

- Door Frame Profile

- Door Lining

- Door Hardwares

- Door Gasket

- Side Panel/Lining

- T-Floor

- Roof Panel/Lining

- Cross Member

- Bottom Side Rail

- Top Side Rail

- Ledge PVC

- Kazoo Drain

- Auto Drain

- Alu Tube

- Auto Drain Center Part

- PVC Drain Pipe

- PVC Plugs f. Drain with Ring and Steel Wire

- Door Screw

- Door Screw Nut

- Door Screw Rubber

- Tapping Screw

- Stainless Blind Rivet

- Lashing Ring

- CSC Plate

- Welding Wire

- Tapping Screw Bit

- Vehicle Parts

- Ship Supplies

- 00. Provisions

- 11. Welfare Items

- 15. Cloth & Linen Products

- 17. Tableware & Galley Utensils

- 19. Clothing

- 21. Rope & Hawsers

- 23. Rigging Equipment & General Deck Items

- 27. Painting Equipment

- 31. Safety Protective Gear

- 33. Safety Equipment

- 35. Hose & Couplings

- 37. Nautical Equipment

- 39. Medicine

- 45. Petroleum Products

- 47. Stationery

- 49. Hardware

- 51. Brushes & Mats

- 55. Cleaning Material & Chemicals

- 59. Pneumatic & Electrical Tools

- 61. Hand Tools

- 63. Cutting Tools

- 65. Measuring Tools

- 69. Screws & Nuts

- 75. Valves & Cocks

- 77. Bearings

- 79. Electrical Equipment

- 81. Packing & Jointing

- 85. Welding Equipment

- 87. Machinery Equipment

- Vehicles

- Lashing Tools

- Logistic Tools

Container PartsCIMC EQUILINK | WHAT ARE ALL THE PARTS AND COMPONENTS OF A SHIPPING CONTAINER?Jan 14,2023Shipping containers are a durable box that can be used for a variety of purposes, but have you ever wondered, “what are shipping containers made of?” Shipping containers are more than just metal welded together, as they have lots of different parts. Of course, you could judge the look, shape, and size of a container outwardly and think that’s all there is to it, but there’s more to its parts than meets the eyes.

What materials are used in making shipping containers?

Every shipping container you see is made primarily from a unique steel material, known as Corten or weathering steel. Corten comprises a group of steel alloys that were fabricated and specifically designed not to require painting. Unlike other types of steel, Corten’s physical properties make it rust-resistant. A thin layer of rust can form on the surface of the container but cannot easily penetrate. This steel is also easy to weld.

Note that other shipping container parts are made of varying materials aside from this primary component of a shipping container.

Features of a shipping container

Most shipping containers you’ll find out there possess most, if not all, of these features.

As the name suggests, cargo doors are two steel doors found at one or sometimes both ends of the container. Some specialty containers will have doors along the side. Aside from loading, cargo doors serve another purpose, and that’s to provide reinforced security for the products in the container against theft. The doors are sealed around the edge to protect the assets from weather intrusion.

The corner casting is specially designed to be strong and withstand high amounts of pressure. Even when the container is fully loaded, the container can be lifted by the corners using crane rigging. The load is evenly distributed on the four corners.

Forklift Pockets

Forklift pockets are where the forklift tines can easily glide through to lift the shipping container. In many standard 20-foot and 40-foot containers, you’ll find the two openings at the bottom edge of the structures. These allow the container to be moved by a forklift without the container tipping off the tines.

Twist Locks

Twist Locks on the corner castings are used when stacking containers. Locking the containers together when stacking them makes them secure and stable.

Cross members comprise the beam and joist of the shipping container. They create space between the container’s flooring and the ground (lifts & supports the container above ground level) to prevent moisture intrusion. They also provide adequate support to the floor of the shipping container. Shipping containers can be modified into comfortable offices and living spaces because of this critical feature.

Shipping containers are formidable and highly functional. They can be modified and customized for storage, work, or living purposes. For more ideas and options on choosing the perfect containers for your project, don’t delay contacting CIMC Equilink for information. Call (86) 21 66867007 or contact us at: info.equilink@cimc.com and our experts will help you find the best solution for your needs and your budget.

Quick Quote

Copyright © 2019 CIMC Equilink - Container Parts

中文

中文